Table of Contents

IiNzuzo zokuSebenzisa isiXhobo sokuPhakamisa esikuMgangatho wokuSebenza kweZibuko

Iimpawu eziPhezulu onokuzijonga kwiZixhobo zokuPhakamisa ukusuka kwiFactory yaseTshayina eBalaseleyo

Inombolo

Igama leMpahla

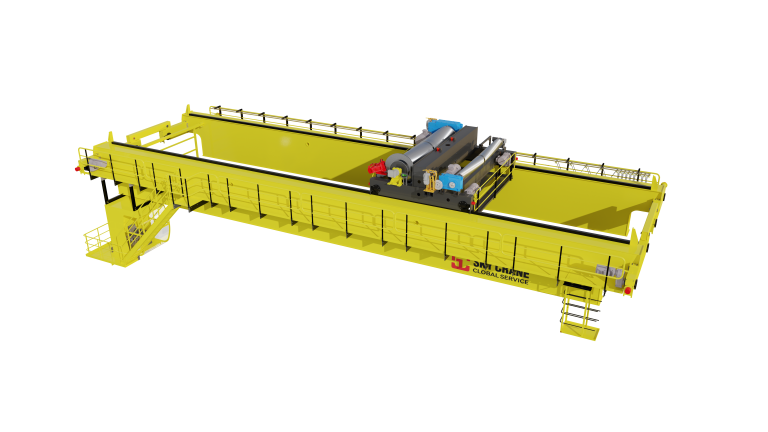

LX ukumiswa kombane crane

| I-Rail – ifakwe kwi-Gantry Crane | i-European-style crane |

| 1 | Harbour crane |

| 2 | Indlela yokugcinwa ngokufanelekileyo kunye nokwandisa uBomi beZixhobo zokuPhakamisa kwiiSetingi zeZibuko |

| 3 | Izixhobo zokuphakamisa zidlala indima ebalulekileyo ekusebenzeni kwamazibuko, ukuququzelela ukuhamba kwemithwalo enzima ukusuka kwiinqanawa ukuya emhlabeni kwaye ngokuphambene noko. Ukuqinisekisa ukusebenza kakuhle kwaba matshini kunye nokwandisa ubomi babo, ukugcinwa okufanelekileyo kubalulekile. Kule nqaku, siza kuxubusha ezinye iindlela zokulondoloza eziphambili ezinokunceda ukugcina izixhobo zokuphakamisa umgangatho ophezulu kwiindawo zechweba.

Ukuhlolwa rhoqo kuyisinyathelo sokuqala sokugcina izixhobo zokunyusa. Ukuhlolwa kufuneka kuqhutywe ngabaqeqeshi abaqeqeshiweyo abanokuchonga nayiphi na imiba enokubakho ngaphambi kokuba inyuke ibe yingxaki enkulu. Olu hlolo kufuneka lufake onke amacandelo esixhobo, kubandakanywa iintambo, iihuku kunye nokulawula. Naziphi na iimpawu zokuguga kufuneka ziqwalaselwe ngokukhawuleza ukuthintela iingozi kunye nexesha lokuphumla. Ngaphezu kokuhlolwa rhoqo, kubalulekile ukulandela ishedyuli engqongqo yokugcina izixhobo zokunyusa. Le shedyuli ifanele ibandakanye imisebenzi efana nokuthambisa amalungu ashukumayo, ukujonga amanqanaba olwelo, kunye nokutshintsha amalungu agugileyo. Ngokulandela ishedyuli yokulungisa, abaqhubi beezibuko banokunqanda ukuphuka okungalindelekanga kwaye baqinisekise ukuba izixhobo zabo zihlala zilungele ukusetyenziswa. Enye inkalo ebalulekileyo yokugcina izixhobo zokunyusa kwiindawo zezibuko luqeqesho. Abaqhubi kufuneka baqeqeshwe ngokufanelekileyo malunga nendlela yokusebenzisa izixhobo ngokukhuselekileyo nangempumelelo. Kufuneka bafundiswe nangendlela yokubona imiba enokubakho baze bayixele kubasebenzi bezolondolozo. Ngotyalo-mali kuqeqesho lwabaqhubi, amazibuko anokunciphisa umngcipheko weengozi kunye nokwandisa ixesha lokuphila kwezixhobo zabo. Ukugcinwa ngokufanelekileyo kukwabalulekile ekugcineni izixhobo zokunyusa. Xa zingasetyenziswa, izixhobo kufuneka zigcinwe kwindawo ecocekileyo neyomileyo ukunqanda umhlwa kunye nomhlwa. Kwakhona kubalulekile ukukhusela izixhobo kumaqondo obushushu agqithisileyo kunye nokufuma, njengoko oku kunokukhawulezisa ukuguga kunye nokukrazula. Ngokugcina izixhobo ngokufanelekileyo, amachweba anokwandisa ixesha lokuphila koomatshini babo bokuphakamisa kunye nokunciphisa imfuno yokulungiswa kweendleko. Ukucocwa rhoqo kungenye indlela ebalulekileyo yokugcina izixhobo zokuphakamisa izixhobo kwiindawo zokubeka izibuko. Uthuli, ubumdaka, nobutyobo bunokuqokelelana kwisixhobo ngokuhamba kwexesha, nto leyo ekhokelela kwimiba yokusebenza kunye nokonakala okunokwenzeka. Ngokucocwa rhoqo izixhobo, amazibuko anokuthintela le miba kwaye aqinisekise ukuba oomatshini babo basebenza kakuhle. Ukucoca kufuneka kwenziwe kusetyenziswa izixhobo ezifanelekileyo kunye nobuchule bokuthintela ukonakalisa amacandelo abuthathaka. Okokugqibela, kubalulekile ukugcina iirekhodi ezineenkcukacha zemisebenzi yogcino lwezixhobo zokuphakamisa. Ezi rekhodi kufuneka zibandakanye iingxelo zokuhlolwa, iishedyuli zolondolozo, kunye naluphi na ulungiso olwenziwayo. Ngokugcina iirekhodi ezichanekileyo, amachweba angakwazi ukulandelela imeko yezixhobo zabo kwaye achonge nayiphi na intsingiselo enokuthi ibonise imfuneko yokugcinwa okongeziweyo. Olu lwazi lunokuba luncedo kwiinjongo zohlahlo lwabiwo-mali kunye nokucwangcisa imisebenzi yogcino lwexesha elizayo. Ekuqukumbeleni, ulondolozo olufanelekileyo lubalulekile ekwandiseni ubomi bezixhobo zokunyusa kwiindawo zezibuko. Ngokwenza uhlolo oluthe rhoqo, ngokulandela ishedyuli yokulondoloza, ukubonelela ngoqeqesho kubaqhubi, ukugcina izixhobo ngokufanelekileyo, ukucoca rhoqo, nokugcina iingxelo ezineenkcukacha, amachweba anokuqinisekisa ukuba oomatshini babo bokuphakamisa basebenza ngokufanelekileyo nangokukhuselekileyo. Ngokutyala imali kulondolozo, amazibuko anokunciphisa umngcipheko weengozi, anciphise ixesha lokuphumla, kwaye andise ubomi bezixhobo zawo. |

| 4 | Harbour crane |

In conclusion, when choosing lifting equipment for ports from the best Chinese factory, it is essential to consider features such as durability, safety, efficiency, versatility, and reputation. By selecting equipment that meets these criteria, you can ensure that your operations run smoothly, safely, and efficiently. Take the time to research and compare different Chinese factories to find the one that best meets your needs and requirements. With the right lifting equipment, you can optimize your port operations and stay ahead of the competition.

How to Properly Maintain and Extend the Lifespan of Lifting Equipment in Port Settings

Lifting equipment plays a crucial role in the operations of ports, facilitating the movement of heavy cargo from ships to land and vice versa. To ensure the smooth functioning of these machines and to extend their lifespan, proper maintenance is essential. In this article, we will discuss some key maintenance practices that can help keep lifting equipment in top condition in port settings.

Regular inspections are the first step in maintaining lifting equipment. Inspections should be conducted by trained professionals who can identify any potential issues before they escalate into major problems. These inspections should cover all components of the equipment, including the cables, hooks, and controls. Any signs of wear and tear should be addressed promptly to prevent accidents and downtime.

In addition to regular inspections, it is important to follow a strict maintenance schedule for lifting equipment. This schedule should include tasks such as lubricating moving parts, checking fluid levels, and replacing worn-out components. By following a maintenance schedule, port operators can prevent unexpected breakdowns and ensure that their equipment is always ready for use.

Another important aspect of maintaining lifting equipment in port settings is training. Operators should be properly trained on how to use the equipment safely and efficiently. They should also be educated on how to spot potential issues and report them to maintenance personnel. By investing in training for operators, ports can reduce the risk of accidents and prolong the lifespan of their equipment.

Proper storage is also crucial for maintaining lifting equipment. When not in use, equipment should be stored in a clean, dry environment to prevent rust and corrosion. It is also important to protect equipment from extreme temperatures and humidity, as these can accelerate wear and tear. By storing equipment properly, ports can extend the lifespan of their lifting machines and reduce the need for costly repairs.

Regular cleaning is another important maintenance practice for lifting equipment in port settings. Dust, dirt, and debris can accumulate on equipment over time, leading to performance issues and potential breakdowns. By regularly cleaning equipment, ports can prevent these issues and ensure that their machines operate smoothly. Cleaning should be done using the appropriate tools and techniques to avoid damaging sensitive components.

Finally, it is important to keep detailed records of maintenance activities for lifting equipment. These records should include inspection reports, maintenance schedules, and any repairs that have been done. By keeping accurate records, ports can track the condition of their equipment and identify any trends that may indicate the need for additional maintenance. This information can also be useful for budgeting purposes and for planning future maintenance activities.

In conclusion, proper maintenance is essential for extending the lifespan of lifting equipment in port settings. By conducting regular inspections, following a maintenance schedule, providing training for operators, storing equipment properly, cleaning regularly, and keeping detailed records, ports can ensure that their lifting machines operate efficiently and safely. By investing in maintenance, ports can reduce the risk of accidents, minimize downtime, and prolong the lifespan of their equipment.