Table of Contents

單樑門式起重機在工業應用上的優勢

序號

| 姓名 | LD電動單樑起重機 |

| 1 | 半龍門起重機 |

| 2 | 歐式起重機 |

| 3 | 港口起重機 |

| 4 | 選擇單樑龍門起重機時要考慮的關鍵特徵 |

如何正確維護及延長單樑門式起重機的使用壽命

單樑門式起重機是建築、製造、物流等各行業的必備設備。這些起重機用於精確且有效率地提升和移動重物。為了確保單樑門式起重機的順利運作並延長其使用壽命,適當的維護至關重要。檢查起重機是否有磨損跡象,例如螺栓鬆動、電纜磨損或零件損壞。請密切注意起升機構,因為這是最容易發生問題的地方。檢查是否有任何異常噪音、振動或可能表明存在問題的洩漏。該計劃應包括日常任務,例如潤滑運動部件、檢查液位和擰緊鬆動的螺栓。保留所有維護活動的詳細記錄,包括日期、時間和所執行工作的性質。這將幫助您追蹤起重機隨著時間的推移的性能,並識別可能需要注意的任何模式或趨勢。將起重機存放在清潔、乾燥、通風良好的區域,以防止生鏽和腐蝕。不使用時,請將起重機蓋好,以防止灰塵、碎片和其他污染物進入。如果起重機暴露在惡劣的天氣條件下,請考慮安裝防護罩或遮蔽物,以使其免受惡劣天氣的影響。使用溫和的清潔劑和水清潔起重機,注意避免使用可能損壞油漆或飾面的磨蝕性清潔劑或溶劑。檢查起重機是否有任何生鏽或腐蝕的跡象,並及時解決這些問題,以防止進一步的損壞。確保所有操作員都經過適當的培訓和認證來操作起重機,並提供持續的培訓以保持他們的技能最新。強調遵循安全協議和程序以防止事故和傷害的重要性。使用來自信譽良好的供應商的正品零件以確保相容性和性能。避免使用可能損害起重機安全性和可靠性的廉價或劣質零件。定期更換磨損或損壞的零件,以防止進一步損壞並確保起重機的持續運作。透過遵循定期維護計劃、進行徹底檢查、正確存放起重機、定期清潔、培訓操作員以及使用高品質的替換零件,您可以確保起重機在未來幾年安全且有效率地運作。請記住,在維護單樑龍門起重機時,預防總是勝於治療。

Key Features to Look for When Choosing a Single Beam Gantry Crane

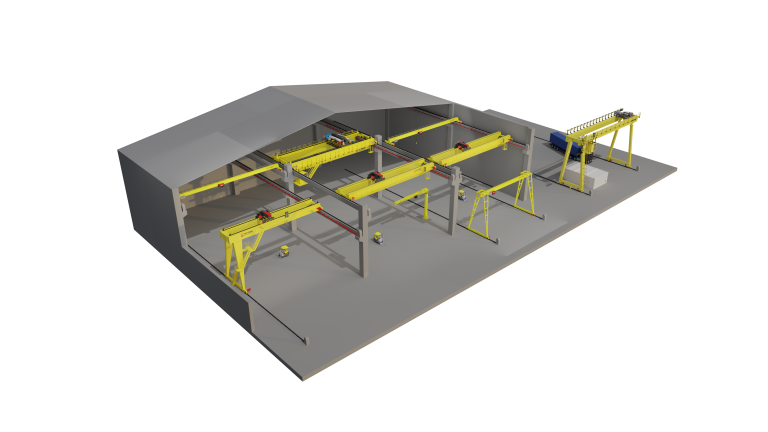

When it comes to choosing a single beam gantry crane, there are several key features that you should consider to ensure that you are getting the best quality crane for your needs. Single beam gantry cranes are commonly used in various industries for lifting and moving heavy loads, so it is important to choose a crane that is reliable, efficient, and safe to use.

One of the most important features to look for when choosing a single beam gantry crane is the lifting capacity. The lifting capacity of a crane refers to the maximum weight that it can lift safely. It is crucial to choose a crane with a lifting capacity that is suitable for the loads that you will be lifting on a regular basis. Choosing a crane with a higher lifting capacity than you need can lead to unnecessary costs, while choosing a crane with a lower lifting capacity can compromise safety and efficiency.

Another key feature to consider when choosing a single beam gantry crane is the span length. The span length of a crane refers to the distance between the two legs of the crane. The span length of the crane should be suitable for the space available in your facility and the size of the loads that you will be lifting. It is important to choose a crane with a span length that allows for easy maneuverability and efficient operation.

The hoisting height is another important feature to consider when choosing a single beam gantry crane. The hoisting height of a crane refers to the maximum height that the crane can lift a load. It is important to choose a crane with a hoisting height that is suitable for the height of your facility and the height of the loads that you will be lifting. Choosing a crane with a hoisting height that is too low can limit the types of loads that you can lift, while choosing a crane with a hoisting height that is too high can lead to unnecessary costs.

The lifting speed is also an important feature to consider when choosing a single beam gantry crane. The lifting speed of a crane refers to the speed at which the crane can lift and lower a load. It is important to choose a crane with a lifting speed that is suitable for the efficiency of your operations. Choosing a crane with a slow lifting speed can lead to delays in production, while choosing a crane with a fast lifting speed can improve productivity.

In addition to these key features, it is also important to consider the safety features of a single beam gantry crane. Safety features such as overload protection, emergency stop buttons, and limit switches are essential for ensuring the safety of operators and preventing accidents. It is important to choose a crane that is equipped with the necessary safety features to protect both workers and equipment.

In conclusion, when choosing a single beam gantry crane, it is important to consider key features such as lifting capacity, span length, hoisting height, lifting speed, and safety features. By carefully evaluating these features, you can ensure that you are choosing a crane that is reliable, efficient, and safe to use. Choose a reputable Chinese supplier for the best quality single beam gantry crane that meets your specific needs.

How to Properly Maintain and Extend the Lifespan of a Single Beam Gantry Crane

Single beam gantry cranes are essential pieces of equipment in various industries, including construction, manufacturing, and logistics. These cranes are used to lift and move heavy loads with precision and efficiency. To ensure the smooth operation of a single beam gantry crane and extend its lifespan, proper maintenance is crucial.

Regular inspections are key to identifying any potential issues before they escalate into major problems. Inspect the crane for signs of wear and tear, such as loose bolts, worn-out cables, or damaged components. Pay close attention to the hoisting mechanism, as this is where most problems tend to occur. Check for any unusual noises, vibrations, or leaks that could indicate a problem.

In addition to regular inspections, it is important to follow a maintenance schedule recommended by the manufacturer. This schedule should include routine tasks such as lubricating moving parts, checking fluid levels, and tightening loose bolts. Keep a detailed record of all maintenance activities, including the date, time, and nature of the work performed. This will help you track the crane’s performance over time and identify any patterns or trends that may require attention.

Proper storage is also essential for maintaining a single beam gantry crane. Store the crane in a clean, dry, and well-ventilated area to prevent rust and corrosion. Keep the crane covered when not in use to protect it from dust, debris, and other contaminants. If the crane is exposed to harsh weather conditions, consider installing a protective cover or shelter to shield it from the elements.

Regularly clean the crane to remove dirt, grease, and other debris that can accumulate on its surfaces. Use a mild detergent and water to clean the crane, taking care to avoid using abrasive cleaners or solvents that could damage the paint or finish. Inspect the crane for any signs of rust or corrosion, and address these issues promptly to prevent further damage.

Properly maintaining a single beam gantry crane also involves training and educating operators on safe and efficient operation. Ensure that all operators are properly trained and certified to operate the crane, and provide ongoing training to keep their skills up to date. Emphasize the importance of following safety protocols and procedures to prevent accidents and injuries.

Investing in high-quality replacement parts and components is another key aspect of maintaining a single beam gantry crane. Use genuine parts from a reputable supplier to ensure compatibility and performance. Avoid using cheap or inferior parts that could compromise the crane’s safety and reliability. Regularly replace worn-out or damaged parts to prevent further damage and ensure the crane’s continued operation.

In conclusion, proper maintenance is essential for extending the lifespan of a single beam gantry crane. By following a regular maintenance schedule, conducting thorough inspections, storing the crane properly, cleaning it regularly, training operators, and using high-quality replacement parts, you can ensure the crane’s safe and efficient operation for years to come. Remember that prevention is always better than cure when it comes to maintaining your single beam gantry crane.