Table of Contents

LDY冶金電動單樑起重機訂製的好處

數字

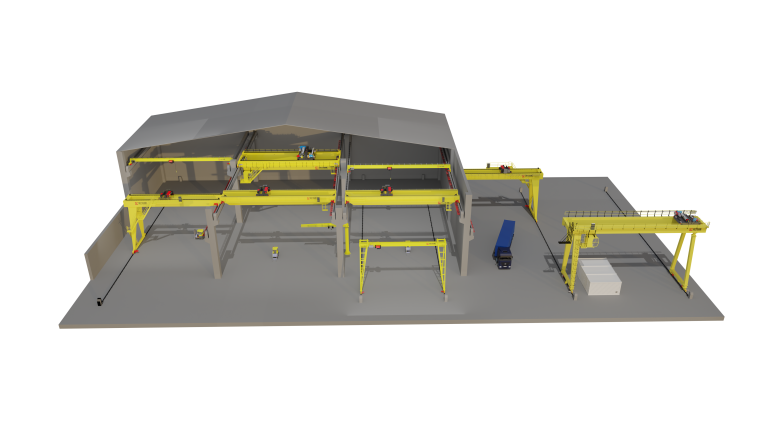

| 姓名 | 5~400T新型吊鉤橋式起重機 |

| 1 | 雙梁門式起重機 |

| 2 | 歐式起重機 |

| 3 | 港口起重機 |

| 4 | 訂購LDY冶金電動單樑起重機時要考慮的主要特點 |

LDY冶金電動單樑起重機客製化如何提升工業作業效率

客製化可以提高工業營運效率的關鍵方法之一是提高生產力。透過客製化起重機以滿足作業的特定要求,公司可以減少停機時間並提高吞吐量。例如,如果一家公司需要一台具有更高起重能力的起重機,LDY可以客製化起重機來滿足這項要求。這意味著起重機將能夠處理更重的負載,從而實現更有效率的操作。透過客製化起重機以適應設施的特定佈局,公司可以降低事故和傷害的風險。例如,如果一家公司的設施空間有限,LDY 可以客製化起重機以適應該空間,從而降低碰撞和其他事故的風險。這可以幫助公司為員工創造一個更安全的工作環境,從長遠來看最終提高效率。透過客製化起重機以滿足工作的特定需求,公司可以減少設備的磨損,從而隨著時間的推移降低維護成本。例如,如果一家公司需要一台可以在極端溫度下運作的起重機,LDY可以客製化起重機來承受這些條件,減少頻繁的維修和保養。 。透過客製化起重機以滿足工作的特定要求,公司可以提高生產力、提高安全性並降低維護成本。作為中國最好的出口商之一,LDY 提供一系列客製化選項,可以幫助公司優化營運。客製化在工業領域至關重要,利用這項服務的公司無疑會看到效率和整體績效的提升。

When it comes to ordering a LDY metallurgical electric single beam crane, there are several key features that you should consider to ensure that you are getting the best product for your needs. LDY metallurgical electric single beam cranes are widely used in various industries, including metallurgy, mining, and manufacturing, due to their high efficiency and reliability. As such, it is important to carefully consider the following features when placing a custom order for a LDY metallurgical electric single beam crane.

One of the most important features to consider when ordering a LDY metallurgical electric single beam crane is the lifting capacity. The lifting capacity of a crane is the maximum weight that it can safely lift and transport. When determining the lifting capacity that you need for your crane, it is important to consider the heaviest load that you will need to lift on a regular basis. It is always better to err on the side of caution and choose a crane with a slightly higher lifting capacity than you think you will need to ensure that it can handle any unexpected loads that may arise.

Another important feature to consider when ordering a LDY metallurgical electric single beam crane is the span length. The span length of a crane is the distance between the two end trucks that support the crane bridge. The span length that you need will depend on the layout of your facility and the distance that the crane will need to travel to lift and transport loads. It is important to carefully measure the span length that you need to ensure that the crane will be able to reach all of the areas where you will need to lift and transport loads.

In addition to lifting capacity and span length, it is also important to consider the lifting height when ordering a LDY metallurgical electric single beam crane. The lifting height of a crane is the maximum height that it can lift a load. When determining the lifting height that you need for your crane, it is important to consider the height of the tallest loads that you will need to lift, as well as any obstacles that may be present in the facility that could limit the height of the crane. It is important to choose a crane with a lifting height that is sufficient for your needs to ensure that you can safely and efficiently lift and transport loads.

Other important features to consider when ordering a LDY metallurgical electric single beam crane include the hoisting speed, trolley speed, and crane travel speed. The hoisting speed is the speed at which the crane can lift and lower loads, while the trolley speed is the speed at which the crane can move loads horizontally along the bridge. The crane travel speed is the speed at which the crane can move along the runway. It is important to choose a crane with speeds that are appropriate for your needs to ensure that you can efficiently move loads throughout your facility.

In conclusion, when ordering a LDY metallurgical electric single beam crane, it is important to carefully consider the lifting capacity, span length, lifting height, hoisting speed, trolley speed, and crane travel speed to ensure that you are getting the best product for your needs. By taking the time to consider these key features, you can ensure that you are investing in a crane that will help you improve efficiency and productivity in your facility.

How LDY Metallurgical Electric Single Beam Crane Customization Can Improve Efficiency in Industrial Operations

In the world of industrial operations, efficiency is key. Companies are constantly looking for ways to streamline their processes and maximize productivity. One way to achieve this is through the customization of equipment, such as the LDY Metallurgical electric single beam crane. As one of the best exporters in China, LDY offers a range of customization options that can help improve efficiency in industrial operations.

Customization is essential in the industrial sector because every operation is unique. What works for one company may not work for another, which is why having the ability to customize equipment is so important. LDY understands this and offers a variety of customization options for their electric single beam cranes. This allows companies to tailor the crane to their specific needs, ensuring that it will perform optimally in their particular operation.

One of the key ways that customization can improve efficiency in industrial operations is by increasing productivity. By customizing a crane to fit the specific requirements of a job, companies can reduce downtime and increase throughput. For example, if a company needs a crane with a higher lifting capacity, LDY can customize the crane to meet this requirement. This means that the crane will be able to handle heavier loads, allowing for more efficient operation.

Customization can also improve safety in industrial operations. By customizing a crane to fit the specific layout of a facility, companies can reduce the risk of accidents and injuries. For example, if a company has limited space in their facility, LDY can customize the crane to fit within that space, reducing the risk of collisions and other accidents. This can help companies create a safer work environment for their employees, ultimately improving efficiency in the long run.

Another way that customization can improve efficiency in industrial operations is by reducing maintenance costs. By customizing a crane to fit the specific needs of a job, companies can reduce wear and tear on the equipment, leading to lower maintenance costs over time. For example, if a company needs a crane that can operate in extreme temperatures, LDY can customize the crane to withstand these conditions, reducing the need for frequent repairs and maintenance.

In conclusion, LDY Metallurgical electric single beam crane customization can greatly improve efficiency in industrial operations. By tailoring the crane to fit the specific requirements of a job, companies can increase productivity, improve safety, and reduce maintenance costs. As one of the best exporters in China, LDY offers a range of customization options that can help companies optimize their operations. Customization is essential in the industrial sector, and companies that take advantage of this service will undoubtedly see improvements in their efficiency and overall performance.