Table of Contents

Kamoo Li-Hoists tsa Motlakase tsa Servo tse Bohlale li Ntlafatsang Katleho ea Ts’ebetso ea Feme

Che.

Lihlahisoa

LD ea motlakase e le ‘ngoe e le ‘ngoe ea beam crane

Single – girder Gantry Crane

| Crene ea mofuta oa Europe | Korene ea boema-kepe |

| 1 | Lithuto tsa Litaba tsa Khokahano e Atlehileng ea Li-Hoists tsa Motlakase tsa Bohlale ho Litlhophiso tsa Feme |

| 2 | Li-hoists tsa motlakase tsa servo tse bohlale li fetotse tsela eo lifeme li sebetsang ka eona, tsa fana ka ts’ebetso e eketsehileng, polokeho le ho nepahala ha mekhoa ea ho sebetsana le thepa. Sehloohong sena, re tla hlahloba lithuto tse ling tsa ho kopanngoa ka katleho ha li-hoist tsa motlakase tsa servo tse bohlale libakeng tsa fektheri, ho bonts’a melemo le tšusumetso eo ba bileng le eona mesebetsing ea tlhahiso.

Tlhahlobo e ‘ngoe e joalo ke semela sa tlhahiso se sebetsanang ka ho khetheha le likarolo tsa likoloi. Ka ho kenya ts’ebetsong li-hoist tse bohlale tsa servo moleng oa bona oa kopano, semela se ile sa khona ho fokotsa haholo nako le mosebetsi o hlokahalang bakeng sa ho phahamisa le ho tsamaisa likarolo tse boima. Bokhoni bo nepahetseng ba ho laola le boits’oaro ba li-hoists bo lumelletse ho kopanngoa ka mokhoa o se nang moeli le mekhoa ea tlhahiso e teng, e leng se hlahisang ts’ebetso e tsitsitseng le e sebetsang hantle. Mohlala o mong ke setsi sa polokelo se sebetsanang le thepa e ngata ea letsatsi le letsatsi. Ka ho nkela li-hoists tsa setso sebaka ka li-hoists tse bohlale tsa servo, setsi sena se ile sa khona ho eketsa tlhahiso le ho fokotsa kotsi ea likotsi tsa mosebetsing. Likarolo tse tsoetseng pele tsa ts’ireletso ea li-hoists, tse kang tšireletso e ngata haholo le theknoloji e khahlanong le ho kheloha, li fane ka khotso ea kelello bakeng sa basebetsi le baokameli ka ho tšoanang, ho etsa bonnete ba hore ho na le sebaka se sireletsehileng sa ho sebetsa. Phuputsong ea boraro, feme ea tšepe e entsoeng ka tšepe e kentse lisebelisoa tse bohlale tsa servo electric hoists. mesebetsing ea bona ea ho tšoara thepa. Bokhoni ba li-hoists ba ho beha hantle le ho tsamaisa lishiti tsa tšepe tse boima le likaroloana tse lumelletsoeng bakeng sa ts’ebetso ea tlhahiso e potlakileng le e nepahetseng haholoanyane. Sena se ile sa fella ka ho fokotseha ho hoholo ha litšila le ts’ebetso e ncha, qetellong ho lebisa tlhokomelong ea litšenyehelo le ho ntlafatsa boleng ba sehlahisoa. Katleho ea lithuto tsena tsa linyeoe e totobatsa tšusumetso ea phetoho eo li-hoists tsa motlakase tsa servo tse bohlale li ka bang le tsona ho litlhophiso tsa fektheri. Ka ho sebelisa theknoloji e tsoetseng pele le bokhoni ba ho iketsetsa, lifeme li ka ntlafatsa mekhoa ea tsona ea ho sebetsana le thepa, ho eketsa tlhahiso, le ho ntlafatsa polokeho ea mosebetsing. litšenyehelo tsa tlhokomelo le nako e telele ea bophelo ba lisebelisoa. Likarolo tse bohlale tsa ho hlahloba le ho hlahloba li-hoists li lumella ho etsa kemiso ea tlhokomelo e matla, ho thibela ho senyeha ho theko e boima le ho fokotsa nako. Ka ho sebelisa matla a thekenoloji e tsoetseng pele, lifeme li ka finyella maemo a phahameng a ts’ebetso, ts’ireletseho le boleng mekhoeng ea bona ea ho sebetsana le thepa. Qetellong, lithuto tsa linyeoe tse hlahisitsoeng sehloohong sena li bontša melemo e bonahalang le liphello tse ntle tsa ho kopanya motlakase oa servo o bohlale. hoist maemong a feme. Ho tloha ho tlhahiso e ntseng e eketseha le ho baballa litšenyehelo ho ea ho ts’ireletseho e ntlafalitsoeng ea sebaka sa mosebetsi le boleng ba sehlahisoa, li-hoist tsena li ipakile e le letlotlo la bohlokoa bakeng sa lits’ebetso tsa sejoale-joale tsa tlhahiso. Ha thekenoloji e ntse e tsoela pele, ho hlakile hore lisebelisoa tsa motlakase tsa servo tse bohlale li tla bapala karolo ea bohlokoa ho bopeng bokamoso ba boiketsetso ba feme le ho sebetsana le thepa. |

| 3 | European-style crane |

| 4 | Harbour crane |

Moreover, intelligent servo electric hoists are designed to be user-friendly and easy to operate. With intuitive interfaces and remote control capabilities, operators can quickly learn how to use these hoists and perform tasks with minimal training. This reduces the learning curve for new employees and ensures that operations can continue smoothly without interruptions.

Overall, intelligent servo electric hoists play a crucial role in improving efficiency in factory operations. Their precision, adaptability, data monitoring capabilities, energy efficiency, and user-friendly design make them an invaluable asset for modern manufacturing facilities. By investing in these advanced hoists, factories can enhance productivity, reduce costs, and create a safer and more efficient working environment for their employees.

In conclusion, intelligent servo electric hoists are a game-changer for factory operations, offering a wide range of benefits that can significantly improve efficiency and productivity. With their advanced technology and innovative features, these hoists are essential tools for modern manufacturing facilities looking to stay competitive in today’s fast-paced industry.

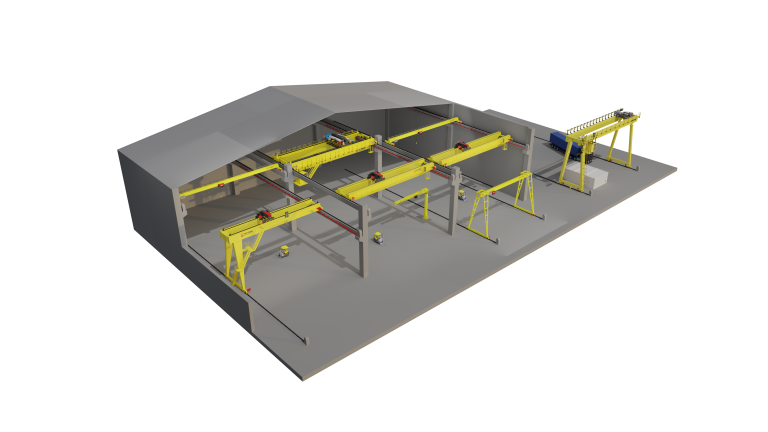

Case Studies of Successful Integration of Intelligent Servo Electric Hoists in Factory Settings

Intelligent servo electric hoists have revolutionized the way factories operate, providing increased efficiency, safety, and precision in material handling processes. In this article, we will explore some case studies of successful integration of intelligent servo electric hoists in factory settings, showcasing the benefits and impact they have had on production operations.

One such case study is a manufacturing plant that specializes in automotive components. By implementing intelligent servo electric hoists in their assembly line, the plant was able to significantly reduce the time and labor required for lifting and moving heavy parts. The hoists’ precise control and automation capabilities allowed for seamless integration with the existing production processes, resulting in a more streamlined and efficient workflow.

Another example is a warehouse facility that handles a high volume of goods on a daily basis. By replacing traditional manual hoists with intelligent servo electric hoists, the facility was able to increase productivity and reduce the risk of workplace injuries. The hoists’ advanced safety features, such as overload protection and anti-sway technology, provided peace of mind for workers and supervisors alike, ensuring a safe working environment.

In a third case study, a metal fabrication plant implemented intelligent servo electric hoists in their material handling operations. The hoists’ ability to precisely position and maneuver heavy metal sheets and components allowed for faster and more accurate production processes. This resulted in a significant reduction in material waste and rework, ultimately leading to cost savings and improved product quality.

The success of these case studies highlights the transformative impact that intelligent servo electric hoists can have on factory settings. By leveraging advanced technology and automation capabilities, factories can optimize their material handling processes, increase productivity, and enhance workplace safety.

Furthermore, the integration of intelligent servo electric hoists in factory settings can also lead to long-term benefits, such as reduced maintenance costs and extended equipment lifespan. The hoists’ smart monitoring and diagnostic features allow for proactive maintenance scheduling, preventing costly breakdowns and downtime.

Overall, the adoption of intelligent servo electric hoists in factory settings represents a significant step towards modernizing and optimizing production operations. By harnessing the power of advanced technology, factories can achieve higher levels of efficiency, safety, and quality in their material handling processes.

In conclusion, the case studies presented in this article demonstrate the tangible benefits and positive outcomes of integrating intelligent servo electric hoists in factory settings. From increased productivity and cost savings to improved workplace safety and product quality, these hoists have proven to be a valuable asset for modern manufacturing facilities. As technology continues to advance, it is clear that intelligent servo electric hoists will play a crucial role in shaping the future of factory automation and material handling.