Table of Contents

Melemo ea ho Sebelisa Gantry Cranes ka Engineering Projects

Nomoro ya Seriale

Lebitso la Sehlooho

| LD ea motlakase e le ‘ngoe e le ‘ngoe ea beam crane | MH rack crane |

| 1 | Crene ea mofuta oa Europe |

| 2 | Korene ea boema-kepe |

| 3 | Mehato ea Tšireletseho le Melao ea Melao ea Ts’ebetso ea Li-Gantry Cranes Chaena |

| 4 | Litlhahiso tsa morao-rao tsa Theknoloji ho Moralo oa Gantry Crane le Tlhahiso ea Likopo tsa Boenjiniere naheng ea China |

Li-cranes tsa Gantry ke lisebelisoa tsa bohlokoa indastering ea boenjiniere, haholo China moo nts’etsopele ea liindasteri e potlakileng le nts’etsopele ea meaho e tsamaisang tlhoko ea tharollo e sebetsang le e tšepahalang ea ho phahamisa. E le e mong oa baetsi ba ka sehloohong ba li-crane tsa gantry lefatšeng, Chaena e ‘nile ea e-ba ka pele ho mekhoa ea theknoloji ea ho qapa le ho etsa thepa. Baetsi ba molemo ka ho fetisisa ba naha ba lula ba sutumelletsa meeli ea se ka khonehang, ba hlahisa litharollo tsa morao-rao tse finyellang litlhoko tse tsoelang pele tsa indasteri.

E ‘ngoe ea mekhoa e ka sehloohong ea moralo le tlhahiso ea gantry crane Chaena ke tšebeliso ea thepa e tsoetseng pele le. mahlale a ho ntlafatsa ts’ebetso le katleho ea mechini ena. Ka mohlala, bahlahisi ba bangata hona joale ba sebelisa li-alloys tsa tšepe tse matla le lisebelisoa tse kopantsoeng ho fokotsa boima ba crane ha ba ntse ba eketsa matla a eona a ho jara. Sena ha se etse feela hore crane e sebelise matla a mangata empa e boetse e lumella ho tsamaea ka potlako le ka mokhoa o nepahetseng haholoanyane, ho ntlafatsa tlhahiso ea kakaretso sebakeng sa mosebetsi.

Nchafatso e ‘ngoe ea bohlokoa ho moralo oa gantry crane ke kopanyo ea theknoloji e bohlale le mekhoa ea ho iketsetsa lintho. Ka ho kenyelletsa li-sensor, lik’hamera le lisebelisoa tse ling tsa ho beha leihlo sebopeho sa crane, bahlahisi ba khona ho bokella lintlha tsa nako ea nnete mabapi le ts’ebetso le boemo ba crane. Lintlha tsena li ka sebelisoa ho ntlafatsa ts’ebetso ea crane, ho thibela ho senyeha, le ho ntlafatsa polokeho. Ho phaella moo, litsamaiso tsa li-automation li ka sebelisoa ho laola crane ka thōko, ho fokotsa tlhokahalo ea ho kenella ka letsoho le ho eketsa katleho.

Lilemong tsa morao tjena, ho boetse ho e-na le ho tsepamisa maikutlo ho ntseng ho eketseha ho tsitsitseng ha moralo oa gantry crane le tlhahiso. Baetsi ba hloahloa ba China ba ntse ba eketsa ho kenyelletsa lisebelisoa tse bolokang tikoloho le mahlale a baballang matla ka har’a likerene tsa bona, ba fokotsa tšusumetso ea bona ea tikoloho le ho thusa ho fihlela lipheo tse kholo tsa naha tsa ts’ireletso. Ka mohlala, bahlahisi ba bang hona joale ba sebelisa mekhoa e tsosolosang ea braking ho tšoara le ho boloka matla nakong ea ts’ebetso ea crane, ho fokotsa tšebeliso ea matla le ho fokotsa mocheso oa carbon.

Ho feta moo, baetsi ba molemo ka ho fetisisa ba Chaena ba boetse ba tsetela haholo lipatlisisong le nts’etsopele ho lula pele ho tlhōlisano. le ho tsoela pele ho qapa moralo oa gantry crane. Ka ho sebelisana ‘moho le liunivesithi, litsi tsa lipatlisiso le balekane ba indasteri, bahlahisi bana ba khona ho fumana theknoloji le boitseanape ba morao-rao, ho etsa bonnete ba hore li-cranes tsa bona li lula li le maemong a holimo indastering. Boitlamo bona ba boqapi bo thusitse baetsi ba li-gantry crane tsa China ho theha botumo bo matla ba boleng le ts’epahalo, ka hare ho naha le kantle ho naha.

Ka kakaretso, lintlafatso tsa morao-rao tsa thekenoloji moqapong le tlhahisong ea likopo tsa boenjiniere naheng ea China li tsamaisa lintlafatso tse kholo ts’ebetsong. , ho sebetsa hantle, le ho tšoarella. Ka ho sebelisa lisebelisoa tse tsoetseng pele, mahlale a bohlale, le litsamaiso tsa othomathike, baetsi ba hloahloa ba China ba khona ho fana ka li-crane tse fihlelang litlhoko tse tsoelang pele tsa indasteri le ho thusa ho tsamaisa tsoelopele mererong ea boenjiniere le ea kaho naheng ka bophara. Ka ho tsepamisitse maikutlo haholo lipatlisisong le nts’etsopele, bahlahisi bana ba maemong a matle a ho tsoela pele ho etella pele ka boqapi ba gantry crane lilemo tse tlang.

Safety Measures and Regulations for Operating Gantry Cranes in China

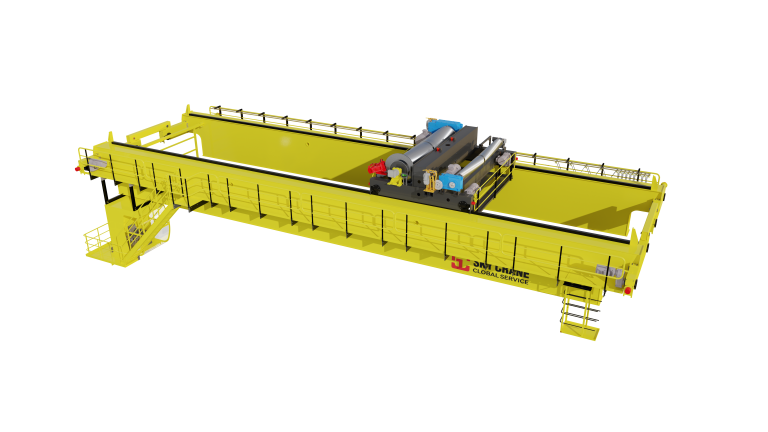

Gantry cranes are essential equipment in the engineering industry, particularly in China where construction and manufacturing activities are booming. These cranes are used to lift and move heavy loads with precision and efficiency, making them indispensable in various engineering projects. However, operating a gantry crane requires strict adherence to safety measures and regulations to prevent accidents and ensure the well-being of workers.

In China, the government has implemented stringent regulations for the operation of gantry cranes to protect workers and prevent workplace accidents. These regulations cover various aspects of crane operation, including maintenance, inspection, and training requirements. It is crucial for companies and operators to comply with these regulations to ensure the safe and efficient operation of gantry cranes.

One of the most important safety measures for operating a gantry crane is regular maintenance and inspection. Gantry cranes are complex machines that require regular maintenance to ensure they are in good working condition. This includes checking for wear and tear, lubricating moving parts, and replacing any damaged components. Regular inspections are also necessary to identify any potential issues before they escalate into serious problems.

Training is another crucial aspect of operating a gantry crane safely. Operators must undergo comprehensive training to learn how to operate the crane properly and safely. This includes understanding the controls, load capacities, and safety procedures. In China, operators are required to obtain a license to operate a gantry crane, which involves passing a written and practical exam to demonstrate their knowledge and skills.

Safety measures for operating gantry cranes also include following proper procedures for lifting and moving loads. Operators must ensure that the load is properly secured and balanced before lifting it. Overloading the crane or lifting an unbalanced load can lead to accidents and injuries. It is essential for operators to follow the manufacturer’s guidelines for load capacities and lifting procedures to prevent accidents.

In addition to following safety measures, operators must also be aware of potential hazards when operating a gantry crane. This includes being mindful of overhead obstacles, slippery surfaces, and other hazards that could pose a risk to the crane and its operators. Operators must also be vigilant when working in close proximity to other workers or equipment to prevent accidents and injuries.

In conclusion, safety measures and regulations for operating gantry cranes in China are essential to protect workers and prevent accidents. Companies and operators must adhere to these regulations to ensure the safe and efficient operation of gantry cranes. By following proper maintenance procedures, undergoing comprehensive training, and being aware of potential hazards, operators can minimize the risk of accidents and injuries when operating gantry cranes. Ultimately, prioritizing safety in crane operations is crucial for the well-being of workers and the success of engineering projects in China.

Latest Technological Innovations in Gantry Crane Design and Manufacturing for Engineering Applications in China

Gantry cranes are an essential piece of equipment in the engineering industry, particularly in China where rapid industrialization and infrastructure development are driving the demand for efficient and reliable lifting solutions. As one of the leading manufacturers of gantry cranes in the world, China has been at the forefront of technological innovations in crane design and manufacturing. The country’s best makers are constantly pushing the boundaries of what is possible, developing cutting-edge solutions that meet the evolving needs of the industry.

One of the key trends in gantry crane design and manufacturing in China is the use of advanced materials and technologies to improve the performance and efficiency of these machines. For example, many manufacturers are now using high-strength steel alloys and composite materials to reduce the weight of the crane while increasing its load-bearing capacity. This not only makes the crane more energy-efficient but also allows for faster and more precise movements, improving overall productivity on the worksite.

Another important innovation in gantry crane design is the integration of smart technologies and automation systems. By incorporating sensors, cameras, and other monitoring devices into the crane’s structure, manufacturers are able to collect real-time data on the crane’s performance and condition. This data can then be used to optimize the crane’s operation, prevent breakdowns, and improve safety. In addition, automation systems can be used to control the crane remotely, reducing the need for manual intervention and increasing efficiency.

In recent years, there has also been a growing focus on sustainability in gantry crane design and manufacturing. China’s best makers are increasingly incorporating eco-friendly materials and energy-efficient technologies into their cranes, reducing their environmental impact and helping to meet the country’s ambitious sustainability goals. For example, some manufacturers are now using regenerative braking systems to capture and store energy during the crane’s operation, reducing energy consumption and lowering carbon emissions.

Furthermore, China’s best makers are also investing heavily in research and development to stay ahead of the competition and continue to innovate in gantry crane design. By collaborating with universities, research institutions, and industry partners, these manufacturers are able to access the latest technologies and expertise, ensuring that their cranes remain at the cutting edge of the industry. This commitment to innovation has helped China’s gantry crane manufacturers to establish a strong reputation for quality and reliability, both domestically and internationally.

Overall, the latest technological innovations in gantry crane design and manufacturing for engineering applications in China are driving significant improvements in performance, efficiency, and sustainability. By leveraging advanced materials, smart technologies, and automation systems, China’s best makers are able to deliver cranes that meet the evolving needs of the industry and help to drive progress in engineering and construction projects across the country. With a strong focus on research and development, these manufacturers are well-positioned to continue leading the way in gantry crane innovation for years to come.