Table of Contents

Faa’iidooyinka Hirgelinta Caqliga leh ee Servo Electric Hoists ee Warshadaha

Sida caqliga leh ee Servo Electric Hoists ay u wanaajiso hufnaanta Hawlaha Warshada

Mid ka mid ah faa’iidooyinka muhiimka ah ee garaadka koronto-dhaliyeyaasha servo waa awooddooda ay ku wanaajiyaan hufnaanta hawlaha warshadaha. Adigoo isticmaalaya matoorada servo-ga iyo nidaamyada kontoroolka horumarsan, kuwa kor u qaadaya waxay qaadi karaan oo ku dhaqaajin karaan culaysyada si sax ah iyo xawaare cajiib ah. Tani kaliya ma dhimayso wakhtiga ay ku qaadato dhamaystirka hawlaha laakiin sidoo kale waxay yaraynaysaa khatarta khaladaadka iyo shilalka, taasoo u horseedaysa jawi shaqo oo badbaado leh oo loogu talagalay shaqaalaha noocyada rarka iyo xaaladaha shaqada. Iyada oo la adeegsan karo goobaha la beddeli karo iyo sifooyin barnaamijka la samayn karo, kor-sareyaashan waxa lagu habayn karaa si ay u daboolaan baahiyaha gaarka ah ee warshadda, haddii ay tahay qaadista mishiinnada culus ama qaybaha jilicsan. Dabacsanaantani waxay u oggolaanaysaa kala duwanaansho weyn oo xagga hawlgallada ah waxayna hubisaa in hawluhu si hufan oo waxtar leh loo dhammaystiri karo Macluumaadkan waxaa loo isticmaali karaa in lagu wanaajiyo socodka shaqada, la ogaado arrimaha suurtagalka ah, iyo in la sameeyo go’aanno xog ogaal ah si loo horumariyo waxtarka guud. Helitaanka xogtan, maareeyayaasha warshaduhu waxay si fiican u qoondayn karaan agabka, dayactirka jadwalka, iyo qorshaynta baahiyaha wax soo saarka mustaqbalka Isticmaalka matoorada servo, kuwan kor u qaadaya waxay cunaan koronto yar marka loo eego koronto dhaqameedyada, taasoo keentay hoos u dhaca kharashyada hawlgalka iyo hoos u dhaca saamaynta deegaanka. Tani ma aha oo kaliya faa’iido u leh xariiqda hoose ee warshadda laakiin sidoo kale waxay la jaan qaadaysaa hadafyada iyo xeerarka waaraya.

Maya.

Badeecooyin

| LD wiishka hal alwaax koronto ah | Single – girder Gantry Crane |

| 1 | wiishka nooca Yurub |

| 2 | wiishka dekedda |

| 3 | Kiiska Daraasaadka Is-dhex-galka Guusha ee Xirfadlayaasha Korontada ee Servo ee Goobaha Warshadda |

| 4 | Harbour crane |

Moreover, intelligent servo electric hoists are designed to be user-friendly and easy to operate. With intuitive interfaces and remote control capabilities, operators can quickly learn how to use these hoists and perform tasks with minimal training. This reduces the learning curve for new employees and ensures that operations can continue smoothly without interruptions.

Overall, intelligent servo electric hoists play a crucial role in improving efficiency in factory operations. Their precision, adaptability, data monitoring capabilities, energy efficiency, and user-friendly design make them an invaluable asset for modern manufacturing facilities. By investing in these advanced hoists, factories can enhance productivity, reduce costs, and create a safer and more efficient working environment for their employees.

In conclusion, intelligent servo electric hoists are a game-changer for factory operations, offering a wide range of benefits that can significantly improve efficiency and productivity. With their advanced technology and innovative features, these hoists are essential tools for modern manufacturing facilities looking to stay competitive in today’s fast-paced industry.

Case Studies of Successful Integration of Intelligent Servo Electric Hoists in Factory Settings

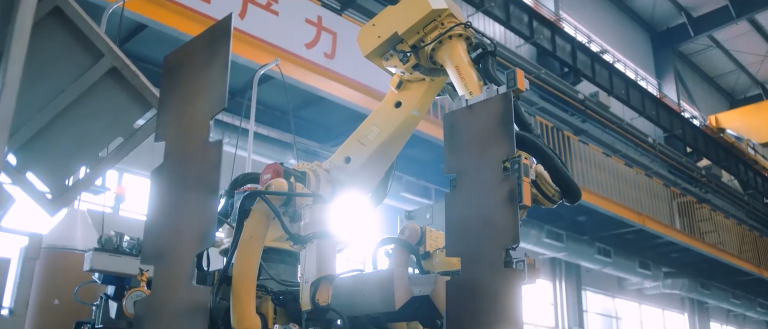

Intelligent servo electric hoists have revolutionized the way factories operate, providing increased efficiency, safety, and precision in material handling processes. In this article, we will explore some case studies of successful integration of intelligent servo electric hoists in factory settings, showcasing the benefits and impact they have had on production operations.

One such case study is a manufacturing plant that specializes in automotive components. By implementing intelligent servo electric hoists in their assembly line, the plant was able to significantly reduce the time and labor required for lifting and moving heavy parts. The hoists’ precise control and automation capabilities allowed for seamless integration with the existing production processes, resulting in a more streamlined and efficient workflow.

Another example is a warehouse facility that handles a high volume of goods on a daily basis. By replacing traditional manual hoists with intelligent servo electric hoists, the facility was able to increase productivity and reduce the risk of workplace injuries. The hoists’ advanced safety features, such as overload protection and anti-sway technology, provided peace of mind for workers and supervisors alike, ensuring a safe working environment.

In a third case study, a metal fabrication plant implemented intelligent servo electric hoists in their material handling operations. The hoists’ ability to precisely position and maneuver heavy metal sheets and components allowed for faster and more accurate production processes. This resulted in a significant reduction in material waste and rework, ultimately leading to cost savings and improved product quality.

The success of these case studies highlights the transformative impact that intelligent servo electric hoists can have on factory settings. By leveraging advanced technology and automation capabilities, factories can optimize their material handling processes, increase productivity, and enhance workplace safety.

Furthermore, the integration of intelligent servo electric hoists in factory settings can also lead to long-term benefits, such as reduced maintenance costs and extended equipment lifespan. The hoists’ smart monitoring and diagnostic features allow for proactive maintenance scheduling, preventing costly breakdowns and downtime.

Overall, the adoption of intelligent servo electric hoists in factory settings represents a significant step towards modernizing and optimizing production operations. By harnessing the power of advanced technology, factories can achieve higher levels of efficiency, safety, and quality in their material handling processes.

In conclusion, the case studies presented in this article demonstrate the tangible benefits and positive outcomes of integrating intelligent servo electric hoists in factory settings. From increased productivity and cost savings to improved workplace safety and product quality, these hoists have proven to be a valuable asset for modern manufacturing facilities. As technology continues to advance, it is clear that intelligent servo electric hoists will play a crucial role in shaping the future of factory automation and material handling.