Table of Contents

Tulaga lelei o Alalaupapa Fa’asa’o-Pa’u Va’ava’a Va’a i Talosaga Fa’aoloa

O se tasi o fa’amanuiaga muamua o va’a alalaupapa-fa’apa’ia o latou fa’alelei tulaga saogalemu. O nei cranes e fausia i mea ma vaega e mafai ona tatalia tulaga pa, ma faʻaitiitia ai le lamatiaga o le mumu. Mo se fa’ata’ita’iga, o le eletise e masani ona tu’u i totonu o fale e pa’u, e taofia ai aloiafi mai le sola ma mu ai kasa po’o le pefu. O lenei tulaga o le saogalemu e taua tele i alamanuia e o’o lava i sina aloiafi e mafai ona o’o atu ai i fa’alavelave mata’utia. E ala i le teu fa’afaigaluegaina o fau laupapa e pa’u, e mafai e kamupani ona fa’aitiitia le fa’alavelave fa’afuase’i, puipuia uma a latou tagata faigaluega ma a latou aseta.

Fa’aopoopo i le saogalemu, e mafai ona fa’aleleia atili le fa’atinoina o galuega. O nei crane ua mamanuina e taulimaina uta mamafa ma le saʻo, faʻatagaina mo le sologa lelei ma le faʻalagolago o mea i totonu o siosiomaga matautia. O le mafai ona si’itia ma felauaiga mea ma le saogalemu ma le lelei e mafai ona taitai atu ai i le faateleina o le gaosiga, aua e mafai e tagata faigaluega ona faʻamaeʻa vave galuega e aunoa ma le popolega faifaipea i lamatiaga e ono tutupu mai. E le gata i lea, o le mamanu malosi o nei crane e mautinoa ai e mafai ona latou faʻaauau pea, e oʻo lava i tulaga luʻitau, lea e manaʻomia mo le faʻatumauina o galuega i fale gaosi oloa e faʻalagolago i le gaosiga faifaipea.

O le isi itu taua o vaʻavaʻavaʻa-faʻalavelave faʻafuaseʻi o lo latou gafatia. O nei cranes e mafai ona faʻapipiʻiina e faʻafetaui ai manaʻoga faʻapitoa o faʻalapotopotoga eseese. Mo se faʻataʻitaʻiga, e mafai ona faʻapipiʻiina i latou i ituaiga eseese o mea faʻapipiʻi, taʻavale, ma faʻatonuga, faʻatagaina i latou e taulimaina le tele o meafaitino ma uta. O lenei fetuutuuna’i e mafai ai ona pa’u alalaupapa va’a talafeagai mo vaega eseese, mai fale gaosi oloa gaosi oloa suauu. A’o fa’atupula’ia alamanuia ma tula’i mai lu’itau fou, ua fa’atuputeleina le taua tele o le mafai ona toe fa’aleleia ma fa’aleleia mea faigaluega, ma fa’ato’a pa’u alalaupapa e maua ai lena fetuutuuna’i.

E le gata i lea, e le gata i lea, e le mafai ona le amana’ia le tau umi o le pa’u alalaupapa. E ui o le uluai tupe teufaafaigaluega atonu e maualuga atu nai lo cranes masani, o le mafai ona faʻasaoina i tulaga o faʻalavelave faʻafuaseʻi, faʻaititia o inisiua, ma faʻaitiitia taimi faʻaletonu e mafai ona avea ai i latou ma filifiliga sili atu ona taugofie i le lumanaʻi. E le gata i lea, o le tumau ma le faʻatuatuaina o nei crane o lona uiga latou te manaʻomia le faʻaitiitia o le tausiga ma le toe sui, ma saofagā atili i le tau-lelei. Kamupani e fa’amuamua le saogalemu ma le lelei o le a latou iloa o fa’amanuiaga o va’a laupapa e fa’ao’o pa’u e sili mamao atu nai lo tau muamua.

Mulimuli ane, o le fa’atupula’ia o le fa’amamafa i le tausisia o fa’atonuga i galuega tau alamanuia o lo’o fa’amamafaina ai le taua o va’a laupapa e fa’apa. O le tele o alamanuia o lo’o i lalo o tulafono fa’atonutonu saogalemu, ma o le fa’aogaina o masini e fetaui ma nei tulaga fa’ata’atia e taua tele mo le ‘alofia o a’afiaga fa’aletulafono ma fa’amautinoa le fa’aauauina o galuega. E ala i le teu fa’afaigaluegaina i totonu o pa’u-fa’amaonia alalaupapa, kamupani e le gata ina fa’aleleia a latou tulafono mo le saogalemu ae fa’aalia ai fo’i lo latou ta’utinoga i le usita’ia o tulafono faatonutonu a alamanuia. fa’aleleia atili le fa’atinoina o galuega, felagolagoma’i, tau fa’aumiumi, ma le tausisia o tulafono faatonutonu. A o faʻaauau pea ona faʻamuamua e pisinisi le saogalemu ma le lelei, o le manaʻoga mo ia meafaigaluega faʻapitoa e foliga mai o le a tupu aʻe, ma avea ai le paʻu-faʻamaonia alalaupapa o se vaega taua o galuega faʻaonaponei.

Tulaga lelei o Alalaupapa Fa’asa’o-Pa’u Va’aiga Va’a I Talosaga Alamanuia

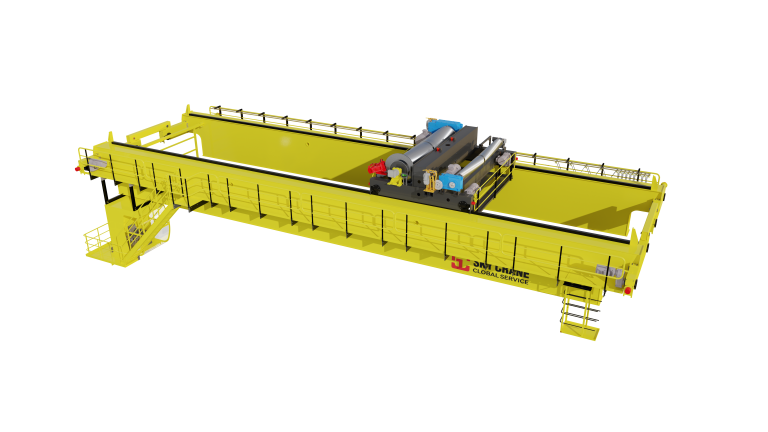

Pa’u-fa’amaonia alalaupapa va’a o vaega taua i fa’aoga eseese tau alamanuia, aemaise i si’osi’omaga o lo’o iai mea e mu po’o mea mata’utia. O le lelei o nei cranes faʻapitoa e tele, ma avea ai ma filifiliga sili mo pisinisi e pei ole petrochemicals, vailaʻau, ma le maina. O se tasi o fa’amanuiaga muamua o va’a alalaupapa fa’alavelave pa’u o lo latou gafatia e fa’aleleia le saogalemu i fale faigaluega. E ala i le faʻaitiitia o le lamatiaga o le mumu i totonu o le ea e mafai ona pa, o nei cranes e puipuia uma tagata faigaluega ma meafaigaluega, ma faʻaitiitia ai le ono tupu o faʻalavelave faʻafuaseʻi. O lenei tulaga saogalemu e taua tele, aua e le gata ina puipuia ai le ola o tagata ae e fesoasoani foi i kamupani ia tausisia tulafono ma tulaga faatonuina mo le saogalemu. siosiomaga faigata. O nei crane e fau ina ia tatalia tulaga ogaoga, e aofia ai le maualuga o le vevela, mea pala, ma uta mamafa. O le iʻuga, e mafai ona latou faʻaogaina lelei i taimi uumi, faʻaitiitia le manaʻomia mo le faʻaleleia faifaipea ma le toe faʻaleleia. O lenei umi e faʻaliliuina i tau faʻagaioiga maualalo mo pisinisi, ona e mafai ona latou faʻalagolago i nei crane mo le faʻatinoina faifaipea e aunoa ma le faʻalavelaveina e masani ona faʻatasi ma meafaigaluega faʻaletonu.

Numera Fa’asologa

| Igoa o Mataupu | LDY metallurgical eletise tasi la’au crane |

| 1 | MH fata crane |

| 2 | Cine fa’a-Europa |

| 3 | Harbour crane |

| 4 | I le fa’aopoopoina i le saogalemu ma le tumau, fa’apapa-fa’amaonia alalaupapa cranes ofo atu fegalegaleai i latou talosaga. E mafai ona fa’avasegaina e fa’amalieina mana’oga fa’apitoa o alamanuia eseese, fa’ataga mo fofo fa’afetaui e fa’aleleia ai le gaosiga. Mo se faʻataʻitaʻiga, o nei crane e mafai ona faʻapipiʻiina i siʻitia tulaga eseese, spans, ma faiga faʻatonutonu, e mafai ai ona latou taulimaina le tele o meafaitino ma galuega. O lenei fetuutuuna’i e sili ona aoga i totonu o siosiomaga fa’apisinisi malosi e ono suia soo ai manaoga fa’agaioiga. O le mea la lea, e mafai e pisinisi ona fa’amalieina a latou galuega ma fa’aleleia atili le lelei atoatoa e ala i le tu’ufa’atasia o alalaupapa fa’ato’a pa i totonu o latou fa’agaioiga.

E le gata i lea, o le alualu i luma fa’atekonolosi i le fa’ata’ita’iga o le crane e fa’ao’o ai mea e fa’aleleia atili ai le fa’atinoga e fa’aleleia ai le poto masani o tagata. O le tele o fa’aonaponei e pa’u alalaupapa fa’ato’aga ua fa’apipi’iina i faiga fa’atonutonu fa’alelei, e aofia ai le fa’aogaina mamao ma mea fa’apitoa. O nei fa’afouga e le gata ina fa’afaigofie ai le si’isi’i ae fa’aitiitia ai fo’i le fa’alavelave fa’aletino i tagata fa’atautaia, ma saofagā i se si’osi’omaga saogalemu ma sili atu le ergonomic. A’o fa’aauau pea le fa’atupuina o alamanuia, o le tu’ufa’atasia o ia tekonolosi ua fa’atuputeleina le taua i le fa’atumauina o le fa’atauva ma fa’amautinoa le fa’amalieina o tagata faigaluega. O le isi fa’amanuiaga taua o va’a laupapa e fa’apa’ia o lo latou sao lea i le fa’atumauina o le si’osi’omaga. E ala i le fa’aitiitia o le lamatiaga o fa’alavelave fa’afuase’i e ono i’u atu ai i masa’a mata’utia po’o fa’amu, o nei crane e taua tele i le puipuia o le si’osi’omaga. E le gata i lea, o la latou mamanu lelei e masani ona iʻu ai i le faʻaitiitia o le faʻaaogaina o le malosi, faʻaititia atili ai le tulaga o le siʻosiʻomaga o galuega tau alamanuia. A’o fa’alauiloa atili e kamupani a latou matafaioi fa’alesiosiomaga, o le fa’aogaina o va’a laupapa e fa’asao-pa’ia e fetaui lelei ma a latou sini fa’aauau. I le fa’ai’uga, o le lelei o le pa-fa’amaonia alalaupapa cranes e tele itufa’ailoga, e aofia ai le saogalemu, tumau, agava’a, fa’atekonolosi fou, ma le fa’atumauina o le si’osi’omaga. A’o feagai pisinisi ma faʻalavelave faʻateleina e faʻaleleia ai le saogalemu ma le lelei aʻo faʻaitiitia a latou aʻafiaga o le siosiomaga, o le manaʻoga mo nei masini faʻapitoa e foliga mai e faʻatupulaia. E ala i le teu fa’afaigaluegaina i luga o le maualuga o le pa-fa’amaonia alalaupapa va’a mai tagata fa’atau oloa ta’uta’ua, e mafai e pisinisi ona fa’amautinoa ua fa’aauupegaina i latou i meafaigaluega sili ona lelei e fa’atautaia ai lu’itau o galuega fa’aonaponei. Mulimuli ane, o le tuʻufaʻatasia o nei crane e le gata e faʻaleleia ai le faʻatinoga o galuega ae faʻaleleia ai foi se aganuu o le saogalemu ma le matafaioi i totonu o fale faigaluega. |

In addition to safety and durability, explosion-proof bridge cranes offer versatility in their applications. They can be customized to meet the specific needs of various industries, allowing for tailored solutions that enhance productivity. For instance, these cranes can be equipped with different lifting capacities, spans, and control systems, enabling them to handle a wide range of materials and tasks. This adaptability is particularly beneficial in dynamic industrial environments where operational requirements may change frequently. Consequently, businesses can optimize their workflows and improve overall efficiency by integrating explosion-proof bridge cranes into their operations.

Furthermore, the technological advancements in explosion-proof crane design have led to improved operational features that enhance user experience. Many modern explosion-proof bridge cranes come equipped with advanced control systems, including remote operation capabilities and automated features. These innovations not only streamline the lifting process but also reduce the physical strain on operators, contributing to a safer and more ergonomic working environment. As industries continue to evolve, the integration of such technologies becomes increasingly important in maintaining competitiveness and ensuring worker satisfaction.

Another significant advantage of explosion-proof bridge cranes is their contribution to environmental sustainability. By minimizing the risk of accidents that could lead to hazardous spills or emissions, these cranes play a vital role in protecting the environment. Additionally, their efficient design often results in lower energy consumption, further reducing the ecological footprint of industrial operations. As companies become more aware of their environmental responsibilities, the adoption of explosion-proof bridge cranes aligns with their sustainability goals.

In conclusion, the advantages of explosion-proof bridge cranes in industrial applications are multifaceted, encompassing safety, durability, versatility, technological innovation, and environmental sustainability. As industries face increasing pressures to enhance safety and efficiency while minimizing their environmental impact, the demand for these specialized cranes is likely to grow. By investing in high-quality explosion-proof bridge cranes from reputable wholesalers, businesses can ensure they are equipped with the best tools to navigate the challenges of modern industrial operations. Ultimately, the integration of these cranes not only enhances operational performance but also fosters a culture of safety and responsibility within the workplace.