Table of Contents

Advantages of Single Beam Gantry Crane for Industrial Applications

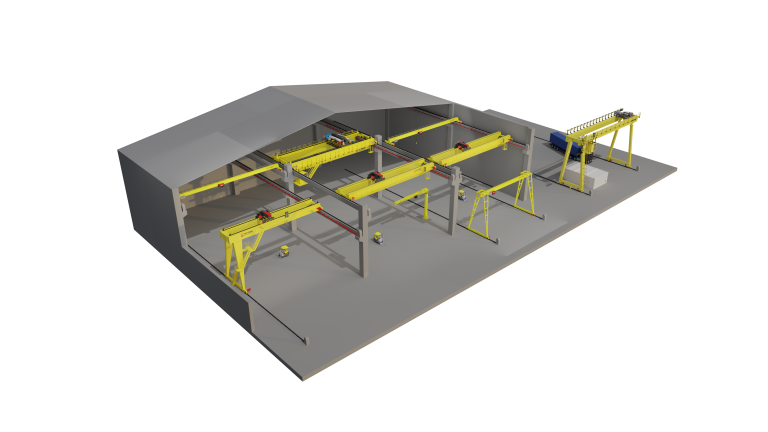

Single beam gantry cranes are a popular choice for industrial applications due to their versatility and efficiency. These cranes are commonly used in warehouses, construction sites, and manufacturing facilities to lift and move heavy loads with ease. In this article, we will explore the advantages of single beam gantry cranes and why they are considered the best choice for industrial use.

One of the main advantages of single beam gantry cranes is their compact design. Unlike traditional overhead cranes that require a complex system of rails and supports, single beam gantry cranes can be easily installed and moved around as needed. This makes them ideal for facilities with limited space or those that need to move the crane to different locations frequently.

| Serial Number | Name |

| 1 | LD electric single beam crane |

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to their compact design, single beam gantry cranes are also highly customizable. They can be tailored to meet the specific needs of the application, whether it be lifting heavy machinery in a manufacturing plant or loading and unloading containers in a warehouse. This flexibility allows for increased efficiency and productivity in the workplace.

Another advantage of single beam gantry cranes is their cost-effectiveness. Compared to other types of cranes, such as double beam gantry cranes or overhead cranes, single beam gantry cranes are more affordable to purchase and maintain. This makes them a practical choice for businesses looking to maximize their budget without sacrificing quality or performance.

Furthermore, single beam gantry cranes are known for their durability and reliability. These cranes are built to withstand heavy loads and harsh working conditions, making them a dependable choice for industrial use. With proper maintenance and care, single beam gantry cranes can last for many years, providing a long-term solution for lifting and moving heavy objects.

In addition to their durability, single beam gantry cranes are also easy to operate. They can be controlled remotely or manually, allowing for precise movements and positioning of the load. This makes them a safe and efficient option for lifting and transporting heavy objects in the workplace.

Overall, single beam gantry cranes offer a wide range of advantages for industrial applications. From their compact design and customization options to their cost-effectiveness and durability, these cranes are a reliable and efficient choice for businesses looking to improve their lifting and moving capabilities. Whether used in a warehouse, construction site, or manufacturing facility, single beam gantry cranes are sure to provide the performance and reliability needed to get the job done.

Key Features to Look for When Choosing a Single Beam Gantry Crane

When it comes to choosing a single beam gantry crane, there are several key features that you should consider to ensure that you are getting the best quality crane for your needs. Single beam gantry cranes are commonly used in various industries for lifting and moving heavy loads, so it is important to choose a crane that is reliable, efficient, and safe to use.

One of the most important features to look for when choosing a single beam gantry crane is the lifting capacity. The lifting capacity of a crane refers to the maximum weight that it can lift safely. It is crucial to choose a crane with a lifting capacity that is suitable for the loads that you will be lifting on a regular basis. Choosing a crane with a higher lifting capacity than you need can lead to unnecessary costs, while choosing a crane with a lower lifting capacity can compromise safety and efficiency.

Another key feature to consider when choosing a single beam gantry crane is the span length. The span length of a crane refers to the distance between the two legs of the crane. The span length of the crane should be suitable for the space available in your facility and the size of the loads that you will be lifting. It is important to choose a crane with a span length that allows for easy maneuverability and efficient operation.

The hoisting height is another important feature to consider when choosing a single beam gantry crane. The hoisting height of a crane refers to the maximum height that the crane can lift a load. It is important to choose a crane with a hoisting height that is suitable for the height of your facility and the height of the loads that you will be lifting. Choosing a crane with a hoisting height that is too low can limit the types of loads that you can lift, while choosing a crane with a hoisting height that is too high can lead to unnecessary costs.

The lifting speed is also an important feature to consider when choosing a single beam gantry crane. The lifting speed of a crane refers to the speed at which the crane can lift and lower a load. It is important to choose a crane with a lifting speed that is suitable for the efficiency of your operations. Choosing a crane with a slow lifting speed can lead to delays in production, while choosing a crane with a fast lifting speed can improve productivity.

In addition to these key features, it is also important to consider the safety features of a single beam gantry crane. Safety features such as overload protection, emergency stop buttons, and limit switches are essential for ensuring the safety of operators and preventing accidents. It is important to choose a crane that is equipped with the necessary safety features to protect both workers and equipment.

In conclusion, when choosing a single beam gantry crane, it is important to consider key features such as lifting capacity, span length, hoisting height, lifting speed, and safety features. By carefully evaluating these features, you can ensure that you are choosing a crane that is reliable, efficient, and safe to use. Choose a reputable Chinese supplier for the best quality single beam gantry crane that meets your specific needs.

How to Properly Maintain and Extend the Lifespan of a Single Beam Gantry Crane

Single beam gantry cranes are essential pieces of equipment in various industries, including construction, manufacturing, and logistics. These cranes are used to lift and move heavy loads with precision and efficiency. To ensure the smooth operation of a single beam gantry crane and extend its lifespan, proper maintenance is crucial.

Regular inspections are key to identifying any potential issues before they escalate into major problems. Inspect the crane for signs of wear and tear, such as loose bolts, worn-out cables, or damaged components. Pay close attention to the hoisting mechanism, as this is where most problems tend to occur. Check for any unusual noises, vibrations, or leaks that could indicate a problem.

In addition to regular inspections, it is important to follow a maintenance schedule recommended by the manufacturer. This schedule should include routine tasks such as lubricating moving parts, checking fluid levels, and tightening loose bolts. Keep a detailed record of all maintenance activities, including the date, time, and nature of the work performed. This will help you track the crane’s performance over time and identify any patterns or trends that may require attention.

Proper storage is also essential for maintaining a single beam gantry crane. Store the crane in a clean, dry, and well-ventilated area to prevent rust and corrosion. Keep the crane covered when not in use to protect it from dust, debris, and other contaminants. If the crane is exposed to harsh weather conditions, consider installing a protective cover or shelter to shield it from the elements.

Regularly clean the crane to remove dirt, grease, and other debris that can accumulate on its surfaces. Use a mild detergent and water to clean the crane, taking care to avoid using abrasive cleaners or solvents that could damage the paint or finish. Inspect the crane for any signs of rust or corrosion, and address these issues promptly to prevent further damage.

Properly maintaining a single beam gantry crane also involves training and educating operators on safe and efficient operation. Ensure that all operators are properly trained and certified to operate the crane, and provide ongoing training to keep their skills up to date. Emphasize the importance of following safety protocols and procedures to prevent accidents and injuries.

Investing in high-quality replacement parts and components is another key aspect of maintaining a single beam gantry crane. Use genuine parts from a reputable supplier to ensure compatibility and performance. Avoid using cheap or inferior parts that could compromise the crane’s safety and reliability. Regularly replace worn-out or damaged parts to prevent further damage and ensure the crane’s continued operation.

In conclusion, proper maintenance is essential for extending the lifespan of a single beam gantry crane. By following a regular maintenance schedule, conducting thorough inspections, storing the crane properly, cleaning it regularly, training operators, and using high-quality replacement parts, you can ensure the crane’s safe and efficient operation for years to come. Remember that prevention is always better than cure when it comes to maintaining your single beam gantry crane.