Inhoudsopgave

Voordelen van het gebruik van portaalkranen bij technische projecten

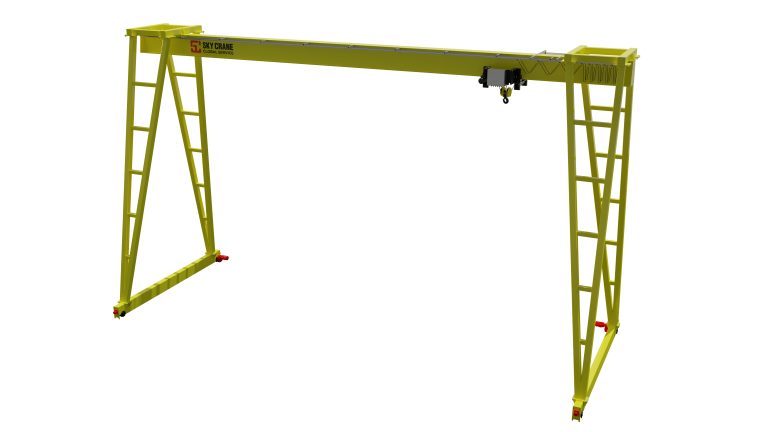

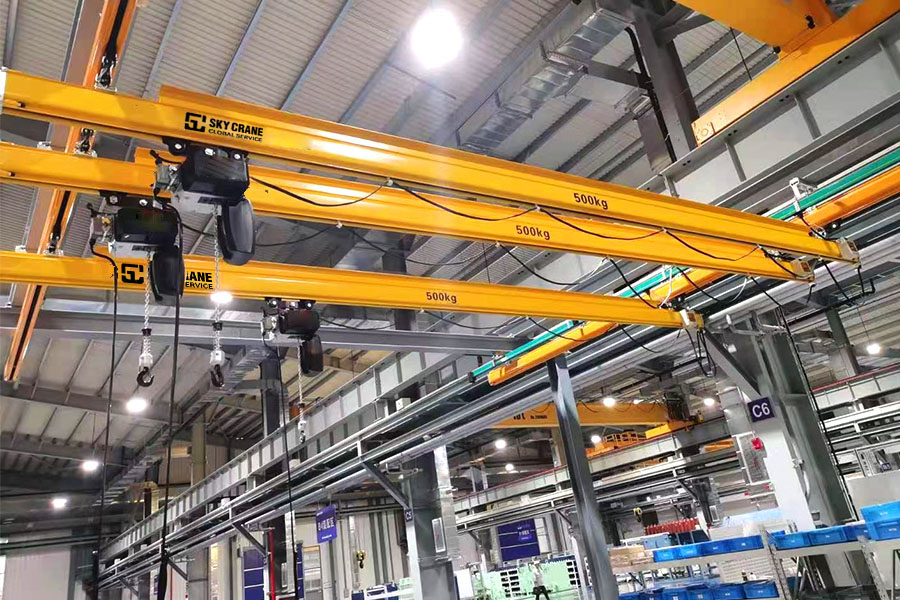

Portaalkranen zijn een essentieel onderdeel van de uitrusting bij technische projecten en bieden een veelzijdige en efficiënte manier om zware materialen op te tillen en te verplaatsen. Deze kranen worden vaak gebruikt op bouwplaatsen, scheepswerven en magazijnen om grote ladingen gemakkelijk te kunnen hanteren. In China zijn er veel fabrikanten die hoogwaardige portaalkranen produceren voor verschillende technische toepassingen.

Een van de belangrijkste voordelen van het gebruik van portaalkranen bij technische projecten is hun vermogen om zware lasten met precisie en controle te heffen. Deze kranen zijn uitgerust met krachtige motoren en stevige stalen balken die gewichten kunnen dragen van enkele tonnen tot enkele honderden tonnen. Dit maakt ze ideaal voor het gemakkelijk heffen en verplaatsen van zware machines, bouwmaterialen en andere omvangrijke voorwerpen.

Naast hun hefvermogen zijn portaalkranen ook zeer wendbaar dankzij hun ontwerp op wielen. Hierdoor kunnen ze gemakkelijk door een werkplek of magazijn worden verplaatst, waardoor ze een veelzijdige en efficiënte optie zijn voor het hanteren van materialen in krappe ruimtes. Portaalkranen kunnen ook worden uitgerust met een verscheidenheid aan accessoires, zoals haken, stroppen en magneten, om tegemoet te komen aan verschillende soorten lasten en hijsvereisten.

Een ander voordeel van het gebruik van portaalkranen in technische projecten is hun duurzaamheid en betrouwbaarheid. Deze kranen zijn gebouwd om de ontberingen van zwaar gebruik te weerstaan, met een robuuste constructie en hoogwaardige componenten die langdurige prestaties garanderen. Dit maakt ze tot een kosteneffectieve investering voor bedrijven die hun mogelijkheden voor materiaalverwerking willen verbeteren en de productiviteit willen verhogen.

Bovendien zijn portaalkranen ontworpen om de veiligheid op de werkplek te vergroten. Deze kranen zijn uitgerust met een reeks veiligheidsvoorzieningen, zoals overbelastingsbeveiligingssystemen, noodstopknoppen en antibotsingsapparatuur, om ongelukken en verwondingen tijdens hijswerkzaamheden te voorkomen. Dit helpt een veiligere werkomgeving voor werknemers te creëren en het risico op schade aan materialen en apparatuur te verminderen.

Als het gaat om het kiezen van een portaalkraan voor een technisch project, is het belangrijk om een gerenommeerde fabrikant te selecteren die producten van hoge kwaliteit aanbiedt en betrouwbare dienstverlening. In China zijn er verschillende fabrikanten die gespecialiseerd zijn in de productie van portaalkranen voor verschillende industrieën, waaronder de bouw, productie en logistiek. Deze fabrikanten gebruiken geavanceerde technologie en strikte kwaliteitscontroleprocessen om ervoor te zorgen dat hun kranen voldoen aan de hoogste normen op het gebied van prestaties en veiligheid.

| Serienummer | Artikelnaam |

| 1 | LD elektrische enkelbalkkraan |

| 2 | MH tandheugelkraan |

| 3 | Kraan in Europese stijl |

| 4 | Havenkraan |

Een van de beste makers van portaalkranen in China staat bekend om hun innovatieve ontwerpen, superieur vakmanschap en uitzonderlijke klantenservice. Ze bieden een breed scala aan portaalkranen die passen bij verschillende hijsvereisten en budgetbeperkingen, waardoor ze een populaire keuze zijn onder technische bedrijven in China en de rest van de wereld.

Kortom, portaalkranen zijn een onmisbaar hulpmiddel voor het hanteren van zware materialen in technische projecten . Hun hefvermogen, manoeuvreerbaarheid, duurzaamheid en veiligheidskenmerken maken ze tot een waardevol bezit voor bedrijven die hun materiaaloverslagactiviteiten willen verbeteren. Door te kiezen voor een gerenommeerde fabrikant die gespecialiseerd is in het produceren van hoogwaardige portaalkranen, kunnen ingenieursbedrijven hun productiviteit, efficiëntie en veiligheid op de werkplek verbeteren.

Veiligheidsmaatregelen en voorschriften voor het bedienen van portaalkranen in China

Nieuwste technologische innovaties in het ontwerp en de productie van portaalkranen voor technische toepassingen in China

Portaalkranen zijn een essentieel onderdeel van de uitrusting in de technische industrie, vooral in China, waar de snelle industrialisatie en infrastructuurontwikkeling de vraag naar efficiënte en betrouwbare hijsoplossingen stimuleren. Als een van de toonaangevende fabrikanten van portaalkranen ter wereld loopt China voorop op het gebied van technologische innovaties op het gebied van kraanontwerp en -productie. De beste makers van het land verleggen voortdurend de grenzen van wat mogelijk is en ontwikkelen geavanceerde oplossingen die voldoen aan de veranderende behoeften van de industrie.

Een van de belangrijkste trends in het ontwerp en de productie van portaalkranen in China is het gebruik van geavanceerde materialen en technologieën om de prestaties en efficiëntie van deze machines te verbeteren. Veel fabrikanten gebruiken nu bijvoorbeeld zeer sterke staallegeringen en composietmaterialen om het gewicht van de kraan te verminderen en tegelijkertijd het draagvermogen te vergroten. Dit maakt de kraan niet alleen energiezuiniger, maar maakt ook snellere en preciezere bewegingen mogelijk, waardoor de algehele productiviteit op de werkplek verbetert.

Een andere belangrijke innovatie in het ontwerp van portaalkranen is de integratie van slimme technologieën en automatiseringssystemen. Door sensoren, camera’s en andere bewakingsapparatuur in de structuur van de kraan te integreren, kunnen fabrikanten realtime gegevens verzamelen over de prestaties en staat van de kraan. Deze gegevens kunnen vervolgens worden gebruikt om de werking van de kraan te optimaliseren, storingen te voorkomen en de veiligheid te verbeteren. Bovendien kunnen automatiseringssystemen worden gebruikt om de kraan op afstand te besturen, waardoor de noodzaak voor handmatige interventie wordt verminderd en de efficiëntie wordt verhoogd.

De laatste jaren is er ook steeds meer aandacht voor duurzaamheid bij het ontwerp en de productie van portaalkranen. De beste makers van China integreren steeds vaker milieuvriendelijke materialen en energie-efficiënte technologieën in hun kranen, waardoor hun impact op het milieu wordt verminderd en de ambitieuze duurzaamheidsdoelstellingen van het land worden verwezenlijkt. Sommige fabrikanten gebruiken nu bijvoorbeeld regeneratieve remsystemen om energie op te vangen en op te slaan tijdens de werking van de kraan, waardoor het energieverbruik wordt verminderd en de CO2-uitstoot wordt verlaagd.

Bovendien investeren de beste Chinese makers ook zwaar in onderzoek en ontwikkeling om de concurrentie voor te blijven en blijven innoveren in het ontwerp van portaalkranen. Door samen te werken met universiteiten, onderzoeksinstellingen en industriële partners hebben deze fabrikanten toegang tot de nieuwste technologieën en expertise, waardoor ze ervoor zorgen dat hun kranen toonaangevend blijven in de sector. Deze toewijding aan innovatie heeft de Chinese portaalkraanfabrikanten geholpen een sterke reputatie op het gebied van kwaliteit en betrouwbaarheid op te bouwen, zowel nationaal als internationaal.

Over het geheel genomen zorgen de nieuwste technologische innovaties op het gebied van het ontwerp en de productie van portaalkranen voor technische toepassingen in China voor aanzienlijke prestatieverbeteringen , efficiëntie en duurzaamheid. Door gebruik te maken van geavanceerde materialen, slimme technologieën en automatiseringssystemen zijn de beste makers van China in staat kranen te leveren die voldoen aan de veranderende behoeften van de industrie en helpen de vooruitgang in engineering- en bouwprojecten in het hele land te stimuleren. Met een sterke focus op onderzoek en ontwikkeling zijn deze fabrikanten goed gepositioneerd om de komende jaren voorop te blijven lopen op het gebied van portaalkraaninnovatie.

Gantry cranes are an essential piece of equipment in the engineering industry, particularly in China where rapid industrialization and infrastructure development are driving the demand for efficient and reliable lifting solutions. As one of the leading manufacturers of gantry cranes in the world, China has been at the forefront of technological innovations in crane design and manufacturing. The country’s best makers are constantly pushing the boundaries of what is possible, developing cutting-edge solutions that meet the evolving needs of the industry.

One of the key trends in gantry crane design and manufacturing in China is the use of advanced materials and technologies to improve the performance and efficiency of these machines. For example, many manufacturers are now using high-strength steel alloys and composite materials to reduce the weight of the crane while increasing its load-bearing capacity. This not only makes the crane more energy-efficient but also allows for faster and more precise movements, improving overall productivity on the worksite.

Another important innovation in gantry crane design is the integration of smart technologies and automation systems. By incorporating sensors, cameras, and other monitoring devices into the crane’s structure, manufacturers are able to collect real-time data on the crane’s performance and condition. This data can then be used to optimize the crane’s operation, prevent breakdowns, and improve safety. In addition, automation systems can be used to control the crane remotely, reducing the need for manual intervention and increasing efficiency.

In recent years, there has also been a growing focus on sustainability in gantry crane design and manufacturing. China’s best makers are increasingly incorporating eco-friendly materials and energy-efficient technologies into their cranes, reducing their environmental impact and helping to meet the country’s ambitious sustainability goals. For example, some manufacturers are now using regenerative braking systems to capture and store energy during the crane’s operation, reducing energy consumption and lowering carbon emissions.

Furthermore, China’s best makers are also investing heavily in research and development to stay ahead of the competition and continue to innovate in gantry crane design. By collaborating with universities, research institutions, and industry partners, these manufacturers are able to access the latest technologies and expertise, ensuring that their cranes remain at the cutting edge of the industry. This commitment to innovation has helped China’s gantry crane manufacturers to establish a strong reputation for quality and reliability, both domestically and internationally.

Overall, the latest technological innovations in gantry crane design and manufacturing for engineering applications in China are driving significant improvements in performance, efficiency, and sustainability. By leveraging advanced materials, smart technologies, and automation systems, China’s best makers are able to deliver cranes that meet the evolving needs of the industry and help to drive progress in engineering and construction projects across the country. With a strong focus on research and development, these manufacturers are well-positioned to continue leading the way in gantry crane innovation for years to come.