Table of Contents

Maintenance Tips for MH Type Electric Hoist Single Beam Gantry Crane

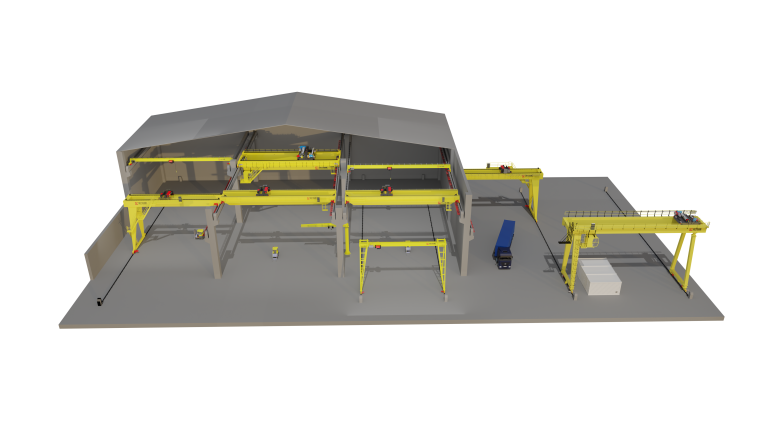

When it comes to industrial equipment, proper maintenance is crucial to ensure optimal performance and longevity. This is especially true for MH type electric hoist single beam gantry cranes, which are commonly used in various industries for lifting and moving heavy loads. As a China Best Exporter of these cranes, we understand the importance of regular maintenance to keep them in top working condition.

One of the key maintenance tips for MH type electric hoist single beam gantry cranes is to regularly inspect all components for any signs of wear or damage. This includes checking the hoist mechanism, trolley, bridge, and runway for any loose or broken parts. Any issues should be addressed promptly to prevent further damage and ensure safe operation of the crane.

In addition to visual inspections, it is important to perform regular lubrication of the crane’s moving parts. Proper lubrication helps reduce friction and wear, extending the lifespan of the crane. It is recommended to use high-quality lubricants that are suitable for the specific components of the crane.

Another important maintenance tip is to check the electrical system of the crane regularly. This includes inspecting the wiring, connections, and controls for any signs of damage or malfunction. Any issues with the electrical system should be addressed by a qualified technician to prevent accidents and ensure the safe operation of the crane.

Regularly checking the brakes of the crane is also essential for safe operation. The brakes should be inspected for proper functioning and adjusted as needed to ensure that the crane can stop safely and securely when needed. Any issues with the brakes should be addressed immediately to prevent accidents and injuries.

It is also important to keep the crane clean and free of debris. Dust, dirt, and other contaminants can build up on the crane’s components and affect its performance. Regular cleaning with a mild detergent and water can help prevent buildup and keep the crane in top working condition.

Regularly inspecting the crane’s structural components is also important for maintenance. This includes checking the beams, columns, and connections for any signs of corrosion or damage. Any issues with the structural integrity of the crane should be addressed promptly to prevent accidents and ensure the safety of workers.

In conclusion, proper maintenance is essential for ensuring the safe and efficient operation of MH type electric hoist single beam gantry cranes. By following these maintenance tips, you can help extend the lifespan of your crane and prevent accidents and injuries. As a China Best Exporter of these cranes, we are committed to providing high-quality products and services to our customers. If you have any questions or need assistance with maintaining your crane, please do not hesitate to contact us.

Advantages of Choosing China’s Best Exporter for Truss Type MH Type Electric Hoist Single Beam Gantry Crane

When it comes to selecting a truss type MH type electric hoist single beam gantry crane, choosing the right supplier is crucial. China has become a leading exporter of industrial equipment, including gantry cranes, due to its high-quality products and competitive prices. In this article, we will discuss the advantages of choosing China’s best exporter for truss type MH type electric hoist single beam gantry crane.

One of the main advantages of selecting China’s best exporter for gantry cranes is the superior quality of their products. Chinese manufacturers are known for their attention to detail and use of high-quality materials in the production of industrial equipment. This ensures that the gantry crane you purchase will be durable, reliable, and able to withstand heavy loads for years to come.

In addition to quality, China’s best exporters also offer a wide range of customization options for truss type MH type electric hoist single beam gantry cranes. Whether you need a specific lifting capacity, span length, or lifting height, Chinese manufacturers can tailor their products to meet your exact requirements. This level of customization ensures that you get a gantry crane that is perfectly suited to your specific needs and applications.

| No. | Product Name |

| 1 | European electric single beam |

| 2 | Semi – gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Furthermore, China’s best exporters are known for their competitive prices. Due to the country’s large manufacturing base and efficient production processes, Chinese manufacturers are able to offer gantry cranes at lower prices compared to other suppliers. This cost advantage allows you to save money on your equipment purchase without compromising on quality or performance.

Another advantage of choosing China’s best exporter for truss type MH type electric hoist single beam gantry crane is the excellent customer service they provide. Chinese manufacturers are committed to ensuring customer satisfaction and will work closely with you throughout the purchasing process. From initial consultation to after-sales support, you can expect prompt and professional assistance from their team of experts.

Moreover, China’s best exporters adhere to strict quality control standards to ensure that their gantry cranes meet international safety and performance requirements. This commitment to quality and safety gives you peace of mind knowing that the equipment you are purchasing is reliable and compliant with industry standards.

In conclusion, selecting China’s best exporter for truss type MH type electric hoist single beam gantry crane offers numerous advantages, including superior quality, customization options, competitive prices, excellent customer service, and adherence to strict quality control standards. By choosing a reputable Chinese manufacturer, you can be confident that you are investing in a high-quality gantry crane that will meet your lifting needs for years to come.