Table of Contents

ຜົນປະໂຫຍດຂອງການນໍາໃຊ້ YZ Casting Bridge Crane ໃນໂຮງງານຈີນ

ບໍ່.

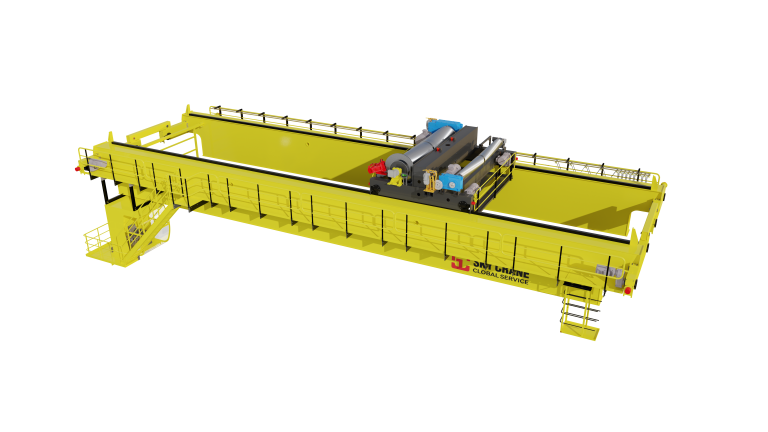

| ຊື່ | LDY metallurgical electric beam crane ດຽວ |

| 1 | ດ່ຽວ – girder Gantry Crane |

| 2 | ເຄນແບບເອີຣົບ |

| 3 | harbour crane |

| 4 | ໂດຍລວມແລ້ວ, YZ casting cranes ສະເຫນີຜົນປະໂຫຍດຫຼາຍດ້ານທີ່ສາມາດຊ່ວຍປັບປຸງປະສິດທິພາບ, ຄວາມປອດໄພ, ແລະຜົນຜະລິດໃນໂຮງງານຈີນ. ຄວາມທົນທານ, versatility, ປະສິດທິພາບ, ຄຸນນະສົມບັດຄວາມປອດໄພ, ຄວາມງ່າຍຂອງການດໍາເນີນງານ, ແລະຄ່າໃຊ້ຈ່າຍປະສິດທິພາບເຮັດໃຫ້ພວກເຂົາເປັນທາງເລືອກທີ່ເຫມາະສົມສໍາລັບສະພາບແວດລ້ອມການຜະລິດຈໍານວນຫຼາຍ. ໂດຍການລົງທຶນໃສ່ລົດເຄນຂົວ YZ, ໂຮງງານສາມາດປັບປຸງການດໍາເນີນງານຂອງເຂົາເຈົ້າແລະສ້າງສະພາບແວດລ້ອມການເຮັດວຽກທີ່ປອດໄພກວ່າແລະມີປະສິດຕິຜົນຫຼາຍຂຶ້ນສໍາລັບພະນັກງານຂອງພວກເຂົາ. |

ຄຸນນະສົມບັດທາງເທີງທີ່ຈະຊອກຫາຢູ່ໃນ YZ Casting Bridge Crane ສໍາລັບໂຮງງານຈີນ

ກໍລະນີການສຶກສາຂອງການປະຕິບັດສົບຜົນສໍາເລັດຂອງ YZ Casting Crane ໃນໂຮງງານຈີນ

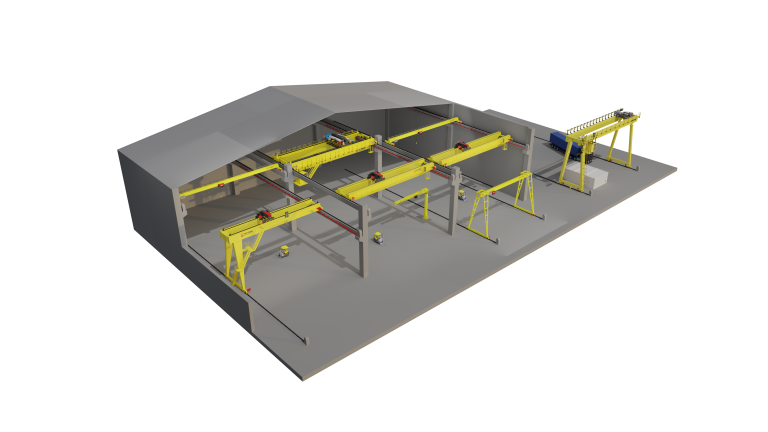

YZ casting cranes ຂົວໄດ້ກາຍເປັນທາງເລືອກທີ່ນິຍົມສໍາລັບໂຮງງານຈີນຈໍານວນຫຼາຍເນື່ອງຈາກຄວາມທົນທານ, ປະສິດທິພາບ, ແລະຄ່າໃຊ້ຈ່າຍປະສິດທິພາບ. ລົດເຄນເຫຼົ່ານີ້ຖືກອອກແບບມາເພື່ອຮັບມືກັບການໂຫຼດຫນັກແລະສະຫນອງການແກ້ໄຂທີ່ປອດໄພແລະເຊື່ອຖືໄດ້ສໍາລັບການເຄື່ອນຍ້າຍວັດສະດຸພາຍໃນໂຮງງານ. ໃນບົດຄວາມນີ້, ພວກເຮົາຈະສໍາຫຼວດບາງກໍລະນີສຶກສາຂອງການປະຕິບັດສົບຜົນສໍາເລັດຂອງ cranes ຂົວ YZ ໃນໂຮງງານຈີນ.

ກໍລະນີສຶກສາຫນຶ່ງດັ່ງກ່າວແມ່ນໂຮງງານຜະລິດເຫຼັກກ້າໃນ Shanghai ທີ່ບໍ່ດົນມານີ້ໄດ້ຕິດຕັ້ງ crane ຂົວຫລໍ່ YZ ເພື່ອປັບປຸງຂະບວນການການຈັດການວັດສະດຸຂອງເຂົາເຈົ້າ. ລົດເຄນສາມາດຍົກແລະຂົນສົ່ງ beam ເຫຼັກຫນັກໄດ້ສະດວກສະບາຍ, ຫຼຸດຜ່ອນເວລາແລະຄວາມພະຍາຍາມທີ່ຈະຍ້າຍວັດສະດຸປະມານຊັ້ນໂຮງງານ. ນີ້ເຮັດໃຫ້ການຜະລິດແລະປະສິດທິພາບຂອງໂຮງງານເພີ່ມຂຶ້ນ, ໃນທີ່ສຸດເຮັດໃຫ້ການປະຫຍັດຄ່າໃຊ້ຈ່າຍແລະການປັບປຸງປະສິດທິພາບໂດຍລວມ.

ຕົວຢ່າງອີກອັນຫນຶ່ງຂອງການປະຕິບັດສົບຜົນສໍາເລັດຂອງ cranes ຂົວ YZ ສາມາດເຫັນໄດ້ໃນໂຮງງານຜະລິດແຜ່ນແພໃນກວາງໂຈວ. ໂຮງງານໄດ້ປະເຊີນກັບສິ່ງທ້າທາຍໃນການຍ້າຍຜ້າມ້ວນຂະໜາດໃຫຍ່ຈາກພື້ນທີ່ໜຶ່ງໄປອີກບ່ອນໜຶ່ງ, ເຊິ່ງເຮັດໃຫ້ການຜະລິດຊັກຊ້າ. ໂດຍການຕິດຕັ້ງເຄນຂົວ YZ, ໂຮງງານສາມາດປັບປຸງຂະບວນການຈັດການວັດສະດຸຂອງພວກເຂົາແລະຫຼຸດຜ່ອນເວລາທີ່ໃຊ້ໃນການເຄື່ອນຍ້າຍວັດສະດຸຢ່າງຫຼວງຫຼາຍ. ນີ້ບໍ່ພຽງແຕ່ປັບປຸງການຜະລິດເທົ່ານັ້ນ, ແຕ່ຍັງຊ່ວຍສ້າງສະພາບແວດລ້ອມການເຮັດວຽກທີ່ປອດໄພກວ່າສໍາລັບພະນັກງານ.

ໃນໂຮງງານຜະລິດໃນ Shenzhen, ຂົວເຄນຫລໍ່ YZ ໄດ້ຖືກຕິດຕັ້ງເພື່ອຊ່ວຍໃນການປະກອບອົງປະກອບເອເລັກໂຕຣນິກ. ລົດເຄນສາມາດຍົກແລະຈັດວາງອົງປະກອບທີ່ລະອຽດອ່ອນທີ່ມີຄວາມແມ່ນຍໍາ, ຫຼຸດຜ່ອນຄວາມສ່ຽງຕໍ່ຄວາມເສຍຫາຍແລະປັບປຸງຄຸນນະພາບໂດຍລວມຂອງຜະລິດຕະພັນສໍາເລັດຮູບ. ນີ້ເຮັດໃຫ້ຄວາມພໍໃຈຂອງລູກຄ້າສູງຂຶ້ນແລະຄວາມຕ້ອງການຜະລິດຕະພັນຂອງໂຮງງານເພີ່ມຂຶ້ນ.

ຜົນປະໂຫຍດທີ່ສໍາຄັນອັນຫນຶ່ງຂອງເຄື່ອງເຄນຂົວ YZ ແມ່ນຄວາມຍືດຫຍຸ່ນແລະການປັບຕົວກັບການຕັ້ງຄ່າໂຮງງານທີ່ແຕກຕ່າງກັນ. ບໍ່ວ່າຈະເປັນໂຮງງານຜະລິດເຫຼັກກ້າ, ໂຮງງານຕັດຫຍິບ, ຫຼືໂຮງງານປະກອບອຸປະກອນເອເລັກໂຕຣນິກ, ເຄື່ອງເຄນເຫຼົ່ານີ້ສາມາດຖືກປັບແຕ່ງເພື່ອຕອບສະຫນອງຄວາມຕ້ອງການສະເພາະຂອງແຕ່ລະສະຖານທີ່. ຄວາມຢືດຢຸ່ນນີ້ຊ່ວຍໃຫ້ການເຊື່ອມໂຍງເຂົ້າກັນໄດ້ຢ່າງບໍ່ຢຸດຢັ້ງໃນຂະບວນການເຮັດວຽກ ແລະຂະບວນການທີ່ມີຢູ່, ເຮັດໃຫ້ມັນເປັນທາງອອກທີ່ເໝາະສົມສໍາລັບອຸດສາຫະກໍາທີ່ຫຼາກຫຼາຍ.

ສະຫຼຸບແລ້ວ, ການປະຕິບັດຢ່າງສໍາເລັດຜົນຂອງເຄນຂົວເຫຼັກ YZ ໃນໂຮງງານຈີນໄດ້ຊ່ວຍປັບປຸງການຜະລິດ, ປະສິດທິພາບ ແລະຄວາມປອດໄພ. ຢູ່ໃນບ່ອນເຮັດວຽກ. cranes ເຫຼົ່ານີ້ໄດ້ພິສູດວ່າເປັນຊັບສິນທີ່ມີຄຸນຄ່າສໍາລັບບໍລິສັດຈໍານວນຫຼາຍ, ສະຫນອງການແກ້ໄຂທີ່ເຊື່ອຖືໄດ້ແລະປະຫຍັດຄ່າໃຊ້ຈ່າຍສໍາລັບຄວາມຕ້ອງການການຈັດການວັດສະດຸ. ດ້ວຍຄວາມທົນທານແລະຄວາມຄ່ອງແຄ້ວ, ເຄນຂົວ YZ ສືບຕໍ່ເປັນທາງເລືອກທີ່ນິຍົມສໍາລັບໂຮງງານທີ່ຊອກຫາການເພີ່ມປະສິດທິພາບການເຮັດວຽກຂອງພວກເຂົາແລະປັບປຸງການປະຕິບັດໂດຍລວມ.

Another important feature to consider is the span of the crane. The span refers to the distance between the runways on which the crane operates. Chinese factories vary in size and layout, so it is crucial to select a YZ casting bridge crane with a span that fits the specific needs of the facility. A crane with a wider span allows for greater coverage and flexibility in moving loads across the factory floor, while a crane with a narrower span is more suitable for smaller workspaces.

In addition to lifting capacity and span, it is essential to consider the lifting height of the YZ casting bridge crane. Chinese factories often have high ceilings and tall storage racks, so selecting a crane with a sufficient lifting height is crucial for reaching and moving loads effectively. YZ casting bridge cranes are available with various lifting heights, allowing factories to choose a crane that meets their specific height requirements.

Safety features are another critical aspect to consider when selecting a YZ casting bridge crane for a Chinese factory. Safety is paramount in any industrial setting, and cranes are no exception. Look for cranes equipped with safety features such as overload protection, emergency stop buttons, and limit switches to prevent accidents and ensure the well-being of workers.

Ease of maintenance and repair is also an important factor to consider when choosing a YZ casting bridge crane for a Chinese factory. Regular maintenance is essential for keeping cranes in optimal working condition and preventing breakdowns. Look for cranes that are easy to maintain and repair, with readily available spare parts and a reliable service network to ensure minimal downtime and maximum productivity.

In conclusion, selecting the right YZ casting bridge crane for a Chinese factory involves considering a range of features, including lifting capacity, span, lifting height, safety features, and ease of maintenance. By carefully evaluating these factors and choosing a crane that meets the specific needs of the facility, Chinese factories can enhance their operations, improve efficiency, and ensure the safety of their workers.

Case Studies of Successful Implementation of YZ Casting Bridge Crane in Chinese Factories

YZ casting bridge cranes have become a popular choice for many Chinese factories due to their durability, efficiency, and cost-effectiveness. These cranes are designed to handle heavy loads and provide a safe and reliable solution for moving materials within a factory setting. In this article, we will explore some case studies of successful implementation of YZ casting bridge cranes in Chinese factories.

One such case study is a steel manufacturing plant in Shanghai that recently installed a YZ casting bridge crane to improve their material handling processes. The crane was able to lift and transport heavy steel beams with ease, reducing the time and effort required to move materials around the factory floor. This resulted in increased productivity and efficiency for the plant, ultimately leading to cost savings and improved overall performance.

Another example of successful implementation of YZ casting bridge cranes can be seen in a textile factory in Guangzhou. The factory was facing challenges with moving large rolls of fabric from one area to another, which was causing delays in production. By installing a YZ casting bridge crane, the factory was able to streamline their material handling processes and significantly reduce the time it took to move materials. This not only improved productivity but also helped to create a safer working environment for employees.

In a manufacturing plant in Shenzhen, a YZ casting bridge crane was installed to help with the assembly of electronic components. The crane was able to lift and position delicate components with precision, reducing the risk of damage and improving the overall quality of the finished products. This resulted in higher customer satisfaction and increased demand for the factory’s products.

One of the key benefits of YZ casting bridge cranes is their versatility and adaptability to different factory settings. Whether it’s a steel manufacturing plant, a textile factory, or an electronics assembly plant, these cranes can be customized to meet the specific needs of each facility. This flexibility allows for seamless integration into existing workflows and processes, making them an ideal solution for a wide range of industries.

In conclusion, the successful implementation of YZ casting bridge cranes in Chinese factories has helped to improve productivity, efficiency, and safety in the workplace. These cranes have proven to be a valuable asset for many companies, providing a reliable and cost-effective solution for material handling needs. With their durability and versatility, YZ casting bridge cranes continue to be a popular choice for factories looking to optimize their operations and improve overall performance.