Table of Contents

Top Chinese Manufacturers of Lifting Equipment for Warehouses

China has established itself as a global leader in manufacturing, particularly in the realm of lifting equipment for warehouses. This sector is crucial for enhancing operational efficiency and safety in logistics and storage facilities. As businesses increasingly seek to optimize their supply chains, the demand for high-quality lifting equipment has surged, prompting several Chinese manufacturers to rise to prominence. Among these, a few stand out due to their innovative designs, robust engineering, and commitment to quality.

One of the foremost manufacturers is Anhui Heli Co., Ltd., which has gained recognition for its extensive range of forklifts and lifting equipment. Established in 1958, Heli has evolved into one of the largest forklift manufacturers in the world. The company\u2019s commitment to research and development has led to the creation of advanced electric and internal combustion forklifts that cater to various warehouse needs. Their products are known for their durability and efficiency, making them a preferred choice for many businesses looking to enhance their material handling capabilities.

Another notable player in the industry is Zhejiang Dingli Machinery Co., Ltd. This company specializes in aerial work platforms and has made significant strides in producing high-quality lifting equipment that meets international safety standards. Dingli\u2019s innovative designs focus on maximizing operational efficiency while ensuring user safety. Their commitment to sustainability is also evident, as they have developed electric-powered lifting equipment that reduces carbon emissions, aligning with global trends toward greener operations.

In addition to these manufacturers, XCMG Group is a key contender in the lifting equipment market. Founded in 1989, XCMG has diversified its product offerings to include a wide range of construction machinery and lifting solutions. Their products, such as tower cranes and mobile elevating work platforms, are engineered to withstand rigorous working conditions, making them ideal for warehouse environments. XCMG\u2019s emphasis on technological advancement and quality control has positioned it as a trusted name in the industry, both domestically and internationally.

Furthermore, the rise of automation in warehouses has led to increased interest in manufacturers like SANY Group. Known for its heavy machinery, SANY has expanded its portfolio to include automated guided vehicles (AGVs) and other intelligent lifting solutions. These innovations not only streamline operations but also enhance safety by reducing the risk of human error. As warehouses increasingly adopt automation, SANY\u2019s products are becoming essential for businesses aiming to stay competitive in a rapidly evolving market.

Moreover, the commitment to quality and customer service among these manufacturers cannot be overlooked. Many of them have established comprehensive after-sales support systems, ensuring that clients receive timely assistance and maintenance services. This focus on customer satisfaction is crucial in building long-term relationships and fostering loyalty among clients.

In conclusion, the landscape of lifting equipment manufacturing in China is marked by several key players who are setting benchmarks in quality, innovation, and customer service. Companies like Anhui Heli, Zhejiang Dingli, XCMG, and SANY are not only meeting the demands of the domestic market but are also making significant inroads into international markets. As the global logistics and warehousing sectors continue to evolve, these manufacturers are well-positioned to lead the way, providing cutting-edge solutions that enhance efficiency and safety in warehouse operations. Their ongoing commitment to innovation and quality ensures that they will remain at the forefront of the industry for years to come.

Innovative Lifting Solutions from Leading Chinese Warehouse Equipment Suppliers

In the rapidly evolving landscape of logistics and warehousing, the demand for innovative lifting solutions has surged, prompting leading Chinese manufacturers to rise to the occasion. These suppliers are at the forefront of developing advanced lifting equipment that not only enhances operational efficiency but also prioritizes safety and reliability. As warehouses increasingly adopt automation and smart technologies, the role of lifting equipment becomes even more critical, necessitating a focus on innovation and adaptability.

Chinese manufacturers have leveraged their extensive experience in engineering and manufacturing to produce a diverse range of lifting equipment tailored to meet the specific needs of modern warehouses. For instance, electric forklifts have gained popularity due to their efficiency and reduced environmental impact compared to traditional internal combustion models. These electric forklifts are designed with advanced battery technology, allowing for longer operational hours and quicker charging times, which ultimately leads to increased productivity in warehouse operations.

Moreover, the integration of smart technology into lifting equipment has transformed how warehouses operate. Many leading Chinese manufacturers are now incorporating IoT (Internet of Things) capabilities into their products. This innovation enables real-time monitoring of equipment performance, predictive maintenance, and enhanced safety features. By utilizing data analytics, warehouse managers can optimize their lifting operations, reduce downtime, and extend the lifespan of their equipment. Consequently, this technological advancement not only improves operational efficiency but also contributes to cost savings in the long run.

| Nr. | Product |

| 1 | LDY metallurgical electric single beam crane |

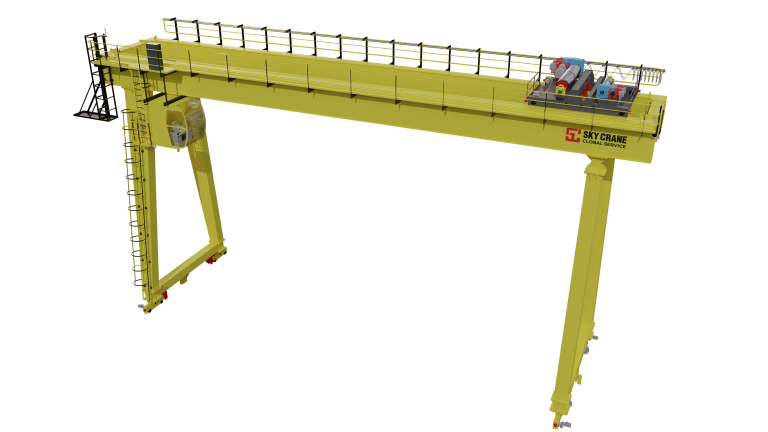

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to electric forklifts, other innovative lifting solutions such as automated guided vehicles (AGVs) and robotic palletizers are gaining traction in the market. These systems are designed to automate repetitive tasks, thereby reducing the reliance on manual labor and minimizing the risk of workplace injuries. Chinese manufacturers have made significant strides in developing AGVs that can navigate complex warehouse layouts with precision, ensuring that goods are transported efficiently from one location to another. This automation not only streamlines operations but also allows human workers to focus on more strategic tasks, thereby enhancing overall productivity.

Furthermore, the emphasis on safety in lifting equipment design cannot be overstated. Leading Chinese manufacturers are committed to adhering to international safety standards, ensuring that their products are equipped with features such as overload protection, emergency stop buttons, and ergonomic designs. These safety measures are crucial in preventing accidents and injuries in busy warehouse environments, where the risk of mishaps can be high. By prioritizing safety, manufacturers not only protect their workforce but also foster a culture of responsibility and care within the organization.

As the global market continues to evolve, the competition among Chinese manufacturers has intensified, driving them to innovate continuously. This competitive landscape has resulted in the development of cost-effective lifting solutions that do not compromise on quality or performance. By investing in research and development, these manufacturers are able to introduce cutting-edge technologies that cater to the unique challenges faced by warehouses today.

In conclusion, the innovative lifting solutions provided by leading Chinese warehouse equipment suppliers are reshaping the logistics industry. With a focus on efficiency, safety, and automation, these manufacturers are not only meeting the current demands of the market but also setting the stage for future advancements. As warehouses continue to adapt to new technologies and operational challenges, the role of these innovative lifting solutions will undoubtedly remain pivotal in driving success and sustainability in the sector.

Comparing Quality and Pricing of Chinese Lifting Equipment for Warehousing Needs

When it comes to equipping a warehouse, the choice of lifting equipment is crucial for ensuring efficiency, safety, and productivity. Among the various global suppliers, Chinese manufacturers have emerged as significant players in the lifting equipment market, offering a wide range of products that cater to diverse warehousing needs. However, as businesses consider sourcing lifting equipment from China, it becomes essential to compare the quality and pricing of these products to make informed decisions.

Chinese manufacturers are known for their ability to produce lifting equipment at competitive prices. This affordability is often attributed to lower labor costs, economies of scale, and a robust supply chain network. As a result, many warehouses find that they can acquire high-quality lifting equipment without straining their budgets. However, it is important to note that not all manufacturers adhere to the same quality standards. Therefore, potential buyers must conduct thorough research to identify reputable suppliers that prioritize quality alongside cost-effectiveness.

In comparing quality, one must consider various factors, including the materials used, the manufacturing processes, and adherence to international safety standards. Many Chinese manufacturers have invested in advanced technology and quality control systems to enhance their production capabilities. This investment has led to the development of lifting equipment that not only meets but often exceeds international safety and performance standards. For instance, equipment such as forklifts, pallet jacks, and hoists are now available with enhanced features that improve operational efficiency and safety, such as load sensors and ergonomic designs.

Moreover, certifications play a significant role in determining the quality of lifting equipment. Many Chinese manufacturers seek certifications such as ISO 9001 for quality management systems and CE marking for compliance with European safety standards. These certifications serve as indicators of a manufacturer\u2019s commitment to producing reliable and safe equipment. Consequently, buyers should prioritize suppliers that can provide documentation of these certifications, as they reflect a manufacturer\u2019s dedication to quality assurance.

While quality is paramount, pricing remains a critical consideration for warehouse operators. The competitive landscape of Chinese manufacturing means that prices can vary significantly between suppliers. It is not uncommon for buyers to encounter a wide range of quotes for similar equipment, which can lead to confusion. To navigate this complexity, it is advisable to obtain multiple quotes and conduct a comparative analysis. This process should not only focus on the initial purchase price but also consider factors such as warranty terms, after-sales support, and the availability of spare parts. A lower upfront cost may be appealing, but if the equipment lacks adequate support or incurs higher maintenance costs, the long-term financial implications could outweigh the initial savings.

Furthermore, engaging with suppliers directly can provide valuable insights into their production capabilities and customer service practices. Establishing a relationship with a manufacturer can lead to better pricing negotiations and more favorable terms. Additionally, many manufacturers are willing to customize equipment to meet specific warehousing needs, which can enhance operational efficiency.

In conclusion, while Chinese manufacturers offer a compelling combination of quality and pricing for lifting equipment, careful consideration is necessary to ensure that the chosen supplier aligns with the specific requirements of a warehouse. By prioritizing quality, seeking reputable manufacturers, and conducting thorough price comparisons, businesses can make informed decisions that enhance their operational capabilities and contribute to long-term success.