Table of Contents

Advantages of LDP Electric Single Beam Cranes in Manufacturing

LDP electric single beam cranes have emerged as a pivotal asset in the manufacturing sector, offering a multitude of advantages that enhance operational efficiency and safety. One of the primary benefits of these cranes is their ability to optimize space utilization within manufacturing facilities. Unlike traditional overhead cranes, the single beam design allows for a more compact structure, which is particularly advantageous in environments where floor space is at a premium. This efficient use of space not only facilitates better workflow but also enables manufacturers to maximize their production capabilities without the need for extensive facility modifications.

In addition to space efficiency, LDP electric single beam cranes are renowned for their ease of operation. Equipped with advanced control systems, these cranes allow operators to maneuver loads with precision and minimal effort. The intuitive controls reduce the learning curve for new operators, thereby enhancing productivity and minimizing the risk of accidents. Furthermore, the electric drive systems employed in these cranes contribute to smoother operation, reducing wear and tear on both the crane and the materials being handled. This reliability translates into lower maintenance costs and increased uptime, which are critical factors in maintaining a competitive edge in the manufacturing industry.

Moreover, safety is a paramount concern in any manufacturing environment, and LDP electric single beam cranes are designed with this in mind. The cranes are equipped with various safety features, such as overload protection, emergency stop buttons, and limit switches, which help prevent accidents and ensure the well-being of personnel. By minimizing the risk of equipment failure or operator error, these cranes contribute to a safer workplace, fostering a culture of safety that is essential for long-term success.

Another significant advantage of LDP electric single beam cranes is their versatility. These cranes can be customized to meet the specific needs of different manufacturing processes, accommodating a wide range of load capacities and operational requirements. Whether it is lifting heavy machinery, transporting materials across the shop floor, or facilitating assembly line operations, the adaptability of these cranes makes them an invaluable tool in various manufacturing settings. This versatility not only enhances operational efficiency but also allows manufacturers to respond swiftly to changing production demands.

Furthermore, the energy efficiency of LDP electric single beam cranes cannot be overlooked. As industries increasingly prioritize sustainability, the electric operation of these cranes aligns with eco-friendly practices. By reducing energy consumption compared to traditional diesel-powered cranes, manufacturers can lower their carbon footprint while also benefiting from reduced operational costs. This commitment to sustainability not only enhances a company’s reputation but also meets the growing demand for environmentally responsible practices in manufacturing.

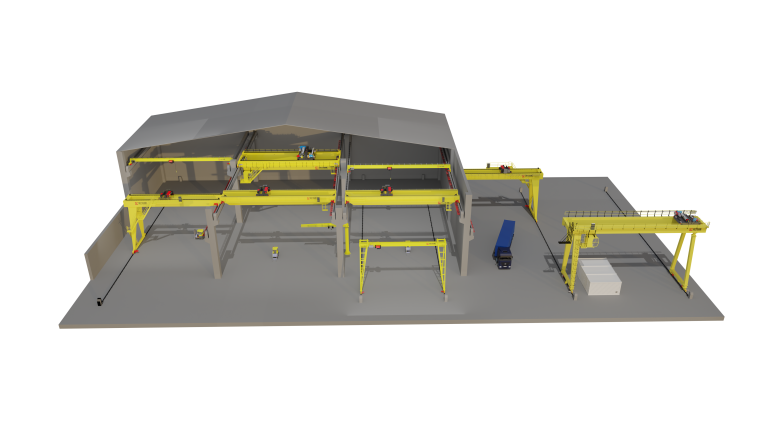

| No. | Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In conclusion, the advantages of LDP electric single beam cranes in manufacturing are manifold, encompassing space optimization, ease of operation, enhanced safety, versatility, and energy efficiency. As manufacturers continue to seek ways to improve productivity and reduce costs, the adoption of these cranes represents a strategic investment that can yield significant returns. By integrating LDP electric single beam cranes into their operations, manufacturers can not only streamline their processes but also create a safer and more sustainable working environment. Ultimately, the implementation of these advanced cranes is a testament to the ongoing evolution of manufacturing technology, paving the way for greater efficiency and innovation in the industry.

Key Features of LDP Electric Single Beam Cranes for Industrial Applications

LDP electric single beam cranes are increasingly recognized for their efficiency and versatility in various industrial applications. These cranes are designed to provide reliable lifting solutions, making them indispensable in manufacturing, warehousing, and construction environments. One of the key features of LDP electric single beam cranes is their robust construction, which ensures durability and longevity. Built with high-quality materials, these cranes can withstand the rigors of heavy-duty operations, thereby minimizing maintenance costs and downtime.

Another significant aspect of LDP electric single beam cranes is their compact design. Unlike traditional cranes that require extensive space for operation, the single beam configuration allows for a more streamlined setup. This compactness not only saves valuable floor space but also enhances maneuverability within tight work areas. Consequently, industries that operate in confined spaces can benefit from the efficient use of their facilities, leading to improved productivity.

In addition to their space-saving design, LDP electric single beam cranes are equipped with advanced lifting mechanisms. These cranes typically feature electric hoists that provide smooth and precise lifting capabilities. The electric hoists are designed to handle various loads, ensuring that they can accommodate the specific requirements of different industrial tasks. Furthermore, the use of electric power contributes to a quieter operation compared to diesel or gas-powered alternatives, making them suitable for environments where noise reduction is a priority.

Safety is another critical feature of LDP electric single beam cranes. These cranes are equipped with multiple safety mechanisms, including overload protection systems and emergency stop buttons. Such features are essential in preventing accidents and ensuring the safety of operators and nearby personnel. Additionally, the cranes often come with user-friendly controls that allow operators to manage lifting operations with precision and ease. This focus on safety not only protects workers but also enhances overall operational efficiency.

Moreover, LDP electric single beam cranes are designed for easy installation and maintenance. Their modular construction allows for straightforward assembly, which can significantly reduce setup time. This ease of installation is particularly beneficial for businesses that require quick deployment of lifting solutions. Furthermore, the cranes are designed with accessibility in mind, enabling maintenance personnel to perform routine checks and repairs without extensive disassembly. This feature not only prolongs the lifespan of the equipment but also ensures that it remains in optimal working condition.

The versatility of LDP electric single beam cranes is another noteworthy characteristic. These cranes can be customized to meet specific operational needs, including varying lifting capacities and span lengths. This adaptability makes them suitable for a wide range of applications, from lifting heavy machinery to transporting materials across production lines. As industries continue to evolve, the ability to tailor equipment to meet unique demands becomes increasingly important.

In conclusion, LDP electric single beam cranes offer a combination of durability, compactness, advanced lifting mechanisms, safety features, ease of installation, and versatility. These key attributes make them an ideal choice for various industrial applications, enhancing productivity while ensuring safety and efficiency. As businesses seek to optimize their operations, the adoption of LDP electric single beam cranes represents a strategic investment in modern lifting technology. By integrating these cranes into their workflows, industries can achieve significant improvements in both performance and operational effectiveness.