Table of Contents

Produsen Cina Top Peralatan Angkat kanggo Gudang

China wis dadi pimpinan global ing manufaktur, utamane ing babagan peralatan angkat kanggo gudang. Sektor iki penting kanggo ningkatake efisiensi operasional lan safety ing fasilitas logistik lan panyimpenan. Nalika bisnis saya tambah akeh ngupaya ngoptimalake rantai pasokan, panjaluk peralatan angkat sing bermutu saya mundhak, nyebabake sawetara pabrikan China dadi misuwur. Ing antarane, sawetara sing misuwur amarga desain inovatif, teknik sing kuat, lan komitmen kanggo kualitas.

Salah sawijining pabrikan sing paling penting yaiku Anhui Heli Co., Ltd., sing wis diakoni kanggo macem-macem forklift lan peralatan angkat. . Madeg ing taun 1958, Heli wis berkembang dadi salah sawijining pabrikan forklift paling gedhe ing donya. Komitmen perusahaan kanggo riset lan pangembangan nyebabake nggawe forklift listrik lan pembakaran internal sing luwih maju sing nyukupi macem-macem kabutuhan gudang. Produk kasebut dikenal kanthi daya tahan lan efisiensi, saengga dadi pilihan sing disenengi kanggo akeh bisnis sing pengin nambah kemampuan penanganan materi.

Pamain liyane sing misuwur ing industri kasebut yaiku Zhejiang Dingli Machinery Co., Ltd. Perusahaan iki duwe spesialisasi ing platform kerja aerial lan wis nggawe langkah sing signifikan kanggo ngasilake peralatan angkat sing cocog karo standar safety internasional. Desain inovatif Dingli fokus kanggo ngoptimalake efisiensi operasional nalika njamin safety pangguna. Komitmen kanggo kelestarian uga katon, amarga wis ngembangake peralatan angkat listrik sing nyuda emisi karbon, selaras karo tren global menyang operasi sing luwih ijo.

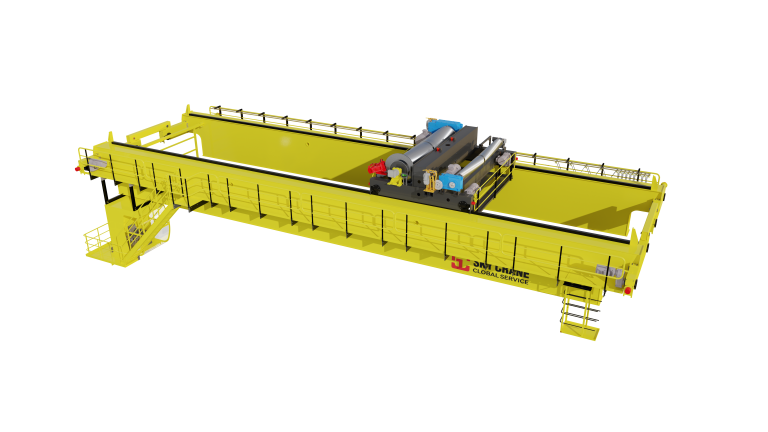

Saliyane manufaktur kasebut, XCMG Group minangka pesaing utama ing pasar peralatan angkat. Founded in 1989, XCMG wis macem-macem kurban produk kanggo kalebu sawetara saka sudhut mesin construction lan ngangkat solusi. Produk kasebut, kayata crane menara lan platform kerja elevasi seluler, dirancang kanggo tahan kahanan kerja sing ketat, saengga cocog kanggo lingkungan gudang. Penekanan XCMG babagan kemajuan teknologi lan kontrol kualitas ndadekake jeneng kasebut minangka jeneng sing dipercaya ing industri kasebut, ing domestik lan internasional.

Dikenal kanggo mesin abot, SANY wis nggedhekake portofolio kanggo nyakup kendaraan dipandu otomatis (AGV) lan solusi ngangkat cerdas liyane. Inovasi kasebut ora mung nyepetake operasi nanging uga nambah safety kanthi nyuda risiko kesalahan manungsa. Amarga gudang tambah akeh nggunakake otomatisasi, produk SANY dadi penting kanggo bisnis sing ngarahake tetep kompetitif ing pasar sing berkembang kanthi cepet. Akeh sing wis nggawe sistem dhukungan sawise-sales lengkap, kanggo mesthekake yen klien nampa pitulungan lan layanan pangopènan sing pas wektune. Fokus ing kepuasan pelanggan iki penting banget kanggo mbangun hubungan jangka panjang lan nuwuhake kasetyan ing antarane para klien.

Kesimpulane, lanskap manufaktur peralatan angkat ing China ditandhani dening sawetara pemain kunci sing nyetel benchmark ing kualitas, inovasi, lan layanan pelanggan . Perusahaan kaya Anhui Heli, Zhejiang Dingli, XCMG, lan SANY ora mung nyukupi panjaluk pasar domestik nanging uga nggawe terobosan sing signifikan menyang pasar internasional. Nalika sektor logistik lan pergudangan global terus berkembang, produsen kasebut duwe posisi sing apik kanggo mimpin, nyedhiyakake solusi canggih sing ningkatake efisiensi lan keamanan ing operasi gudang. Komitmen sing terus-terusan kanggo inovasi lan kualitas mesthekake yen dheweke bakal tetep ing ngarep industri nganti pirang-pirang taun.

Solusi Angkat Inovatif saka Supplier Peralatan Gudang Cina Utama

Ing lanskap logistik lan pergudangan sing berkembang kanthi cepet, panjaluk solusi ngangkat inovatif saya mundhak, nyebabake produsen China sing misuwur. Pemasok iki dadi sing paling ngarep kanggo ngembangake peralatan ngangkat canggih sing ora mung nambah efisiensi operasional nanging uga prioritas safety lan linuwih. Nalika gudang tambah akeh nggunakake otomatisasi lan teknologi cerdas, peran peralatan ngangkat dadi luwih kritis, mbutuhake fokus ing inovasi lan adaptasi.

Produsen Cina wis nggunakake pengalaman ekstensif ing teknik lan manufaktur kanggo ngasilake macem-macem peralatan angkat sing disesuaikan nyukupi kabutuhan tartamtu saka gudang modern. Contone, forklift listrik wis entuk popularitas amarga efisiensi lan nyuda pengaruh lingkungan dibandhingake karo model pembakaran internal tradisional. Forklift listrik iki dirancang kanthi teknologi baterei sing canggih, ngidini jam operasional luwih suwe lan wektu pangisian daya luwih cepet, sing pungkasane bisa nambah produktivitas ing operasi gudang.

Saliyane, integrasi teknologi cerdas menyang peralatan ngangkat wis ngowahi cara gudang. Akeh pabrikan Cina sing misuwur saiki nggabungake kemampuan IoT (Internet of Things) menyang produke. Inovasi iki ngidini ngawasi kinerja peralatan kanthi nyata, pangopènan prediktif, lan fitur safety sing ditingkatake. Kanthi nggunakake analytics data, manajer gudang bisa ngoptimalake operasi angkat, nyuda downtime, lan nambah umur peralatan. Akibaté, kemajuan teknologi iki ora mung nambah efisiensi operasional nanging uga nyumbang kanggo ngirit biaya ing jangka panjang.

| Nr. | Produk |

| 1 | LDY metalurgi listrik balok tunggal crane |

| 2 | Karet – Gantry Crane kesel |

| 3 | crane gaya Eropa |

| 4 | Kran pelabuhan |

Bandingake Kualitas lan Rega Peralatan Angkat Cina kanggo Kebutuhan Gudang

Nalika nerangake nglengkapi gudang, pilihan peralatan ngangkat iku penting kanggo njamin efisiensi, safety, lan produktivitas. Ing antarane macem-macem pemasok global, produsen China wis dadi pemain penting ing pasar peralatan angkat, nawakake macem-macem produk sing nyukupi kabutuhan gudang sing beda-beda. Nanging, amarga bisnis nganggep sumber peralatan angkat saka China, dadi penting kanggo mbandhingake kualitas lan rega produk kasebut kanggo nggawe keputusan sing tepat.

Produsen China dikenal amarga kemampuane ngasilake peralatan angkat kanthi rega sing kompetitif. Keterjangkauan iki asring disebabake biaya tenaga kerja sing murah, skala ekonomi, lan jaringan rantai pasokan sing kuwat. Akibaté, akeh gudang nemokake manawa bisa entuk peralatan ngangkat sing berkualitas tinggi tanpa ngganggu anggaran. Nanging, penting kanggo dicathet yen ora kabeh pabrikan netepi standar kualitas sing padha. Mula, para panuku potensial kudu nindakake riset kanthi tliti kanggo ngenali panyedhiya sing biso dipercoyo sing ngutamakake kualitas bebarengan karo biaya-efektifitas.

Kanggo mbandhingake kualitas, siji kudu nimbang macem-macem faktor, kalebu bahan sing digunakake, proses manufaktur, lan ketaatan standar safety internasional. Akeh manufaktur Cina wis nandur modal ing teknologi canggih lan sistem kontrol kualitas kanggo nambah kemampuan produksi. Investasi iki nyebabake pangembangan peralatan angkat sing ora mung cocog nanging asring ngluwihi standar keamanan lan kinerja internasional. Contone, peralatan kayata forklift, pallet jacks, lan hoist saiki kasedhiya kanthi fitur sing nambah efisiensi lan safety operasional, kayata sensor beban lan desain ergonomis.

Lan, sertifikasi nduweni peran penting kanggo nemtokake kualitas peralatan angkat. . Akeh manufaktur China njaluk sertifikasi kayata ISO 9001 kanggo sistem manajemen kualitas lan tandha CE kanggo tundhuk karo standar safety Eropa. Sertifikasi kasebut minangka indikator komitmen pabrikan kanggo ngasilake peralatan sing dipercaya lan aman. Akibate, para panuku kudu menehi prioritas marang pemasok sing bisa nyedhiyakake dokumentasi sertifikasi kasebut, amarga nggambarake pengabdian pabrikan kanggo jaminan kualitas.

Nalika kualitas paling penting, rega tetep dadi pertimbangan kritis kanggo operator gudang. Lanskap kompetitif manufaktur Cina tegese rega bisa beda-beda ing antarane pemasok. Iku ora aneh kanggo panuku nemokke sawetara saka sudhut kuotasi kanggo peralatan padha, kang bisa mimpin kanggo kebingungan. Kanggo njelajah kerumitan iki, disaranake njupuk pirang-pirang kuotasi lan nganakake analisis komparatif. Proses iki ora mung kudu fokus ing rega tuku awal nanging uga nimbang faktor kayata syarat garansi, dhukungan sawise adol, lan kasedhiyan suku cadang. Biaya ngarep sing luwih murah bisa uga nyenengake, nanging yen peralatan kasebut ora duwe dhukungan sing nyukupi utawa entuk biaya pangopènan sing luwih dhuwur, implikasi finansial jangka panjang bisa luwih gedhe tinimbang tabungan awal. laku layanan pelanggan. Nggawe hubungan karo pabrikan bisa nyebabake negosiasi rega sing luwih apik lan syarat sing luwih apik. Kajaba iku, akeh manufaktur sing gelem ngatur peralatan kanggo nyukupi kabutuhan warehousing tartamtu, sing bisa ningkatake efisiensi operasional.

Kesimpulane, nalika manufaktur China nawakake kombinasi kualitas lan rega sing apik kanggo peralatan angkat, pertimbangan sing ati-ati perlu kanggo mesthekake yen pilihan sing dipilih. supplier selaras karo syarat tartamtu saka gudang. Kanthi ngutamakake kualitas, golek manufaktur sing biso dipercoyo, lan nindakake perbandingan rega sing lengkap, bisnis bisa nggawe keputusan sing tepat sing ningkatake kemampuan operasional lan menehi kontribusi kanggo sukses jangka panjang.

When it comes to equipping a warehouse, the choice of lifting equipment is crucial for ensuring efficiency, safety, and productivity. Among the various global suppliers, Chinese manufacturers have emerged as significant players in the lifting equipment market, offering a wide range of products that cater to diverse warehousing needs. However, as businesses consider sourcing lifting equipment from China, it becomes essential to compare the quality and pricing of these products to make informed decisions.

Chinese manufacturers are known for their ability to produce lifting equipment at competitive prices. This affordability is often attributed to lower labor costs, economies of scale, and a robust supply chain network. As a result, many warehouses find that they can acquire high-quality lifting equipment without straining their budgets. However, it is important to note that not all manufacturers adhere to the same quality standards. Therefore, potential buyers must conduct thorough research to identify reputable suppliers that prioritize quality alongside cost-effectiveness.

In comparing quality, one must consider various factors, including the materials used, the manufacturing processes, and adherence to international safety standards. Many Chinese manufacturers have invested in advanced technology and quality control systems to enhance their production capabilities. This investment has led to the development of lifting equipment that not only meets but often exceeds international safety and performance standards. For instance, equipment such as forklifts, pallet jacks, and hoists are now available with enhanced features that improve operational efficiency and safety, such as load sensors and ergonomic designs.

Moreover, certifications play a significant role in determining the quality of lifting equipment. Many Chinese manufacturers seek certifications such as ISO 9001 for quality management systems and CE marking for compliance with European safety standards. These certifications serve as indicators of a manufacturer\’s commitment to producing reliable and safe equipment. Consequently, buyers should prioritize suppliers that can provide documentation of these certifications, as they reflect a manufacturer\’s dedication to quality assurance.

While quality is paramount, pricing remains a critical consideration for warehouse operators. The competitive landscape of Chinese manufacturing means that prices can vary significantly between suppliers. It is not uncommon for buyers to encounter a wide range of quotes for similar equipment, which can lead to confusion. To navigate this complexity, it is advisable to obtain multiple quotes and conduct a comparative analysis. This process should not only focus on the initial purchase price but also consider factors such as warranty terms, after-sales support, and the availability of spare parts. A lower upfront cost may be appealing, but if the equipment lacks adequate support or incurs higher maintenance costs, the long-term financial implications could outweigh the initial savings.

Furthermore, engaging with suppliers directly can provide valuable insights into their production capabilities and customer service practices. Establishing a relationship with a manufacturer can lead to better pricing negotiations and more favorable terms. Additionally, many manufacturers are willing to customize equipment to meet specific warehousing needs, which can enhance operational efficiency.

In conclusion, while Chinese manufacturers offer a compelling combination of quality and pricing for lifting equipment, careful consideration is necessary to ensure that the chosen supplier aligns with the specific requirements of a warehouse. By prioritizing quality, seeking reputable manufacturers, and conducting thorough price comparisons, businesses can make informed decisions that enhance their operational capabilities and contribute to long-term success.