Table of Contents

Uru nke LDP Electric Single Beam Cranes na nrụpụta

Mba.

Aha

| QD n’elu isi crane nwere mkpuchi mkpuchi.5-800/150T | Ugboro abụọ – girder Gantry Crane |

| 1 | kreenu ụdị nke Europe |

| 2 | Herbour crane |

| 3 | N’ikpeazụ, uru nke LDP electric single beam cranes na n’ichepụta ihe dị iche iche, gụnyere njikarịcha ohere, ịdị mfe nke ọrụ, nkwalite nchekwa, ntụgharị, na ike ike. Ka ndị na-emepụta ihe na-aga n’ihu na-achọ ụzọ ha ga-esi kwalite mmepụta na ibelata ọnụ ahịa, nkuchi nke cranes ndị a na-anọchite anya ntinye ego dị mkpa nke nwere ike iwepụta nnukwu nloghachi. Site na ijikọ ọkụ eletrik LDP otu cranes n’ime ọrụ ha, ndị na-emepụta nwere ike ọ bụghị naanị ịhazi usoro ha kamakwa ịmepụta ebe ọrụ dị nchebe na nke na-adịgide adịgide. N’ikpeazụ, mmejuputa cranes ndị a dị elu bụ ihe akaebe maka mgbanwe na-aga n’ihu nke nkà na ụzụ mmepụta ihe, na-emepe ụzọ maka ịrụ ọrụ dị ukwuu na mmepụta ihe na ụlọ ọrụ ahụ. |

| 4 | Ụdị isi nke LDP Electric Single Beam Cranes maka ngwa nrụpụta |

LDP electric single beam cranes na-amatawanye nke ọma maka arụmọrụ ha na ngwa ngwa dị iche iche nke ụlọ ọrụ mmepụta ihe. Emebere cranes ndị a iji nye ihe ngwọta ebuli elu a pụrụ ịdabere na ya, na-eme ka ha dị mkpa na nrụpụta, nkwakọba ihe, na gburugburu ebe owuwu ihe. Otu n’ime ihe ndị dị mkpa nke LDP electric single beam cranes bụ ihe owuwu ha siri ike, nke na-eme ka ọ dị ogologo ndụ na ogologo ndụ. Ejiri ihe dị elu rụọ ọrụ, cranes ndị a nwere ike iguzogide ihe siri ike nke arụ ọrụ dị arọ, si otú ahụ na-ebelata ụgwọ ọrụ na oge nkwụsị.

Akụkụ ọzọ dị ịrịba ama nke LDP electric single beam cranes bụ kọmpat nhazi ha. N’adịghị ka cranes ọdịnala na-achọ ohere sara mbara maka ịrụ ọrụ, nhazi nke otu beam na-enye ohere maka nhazi nke ọma. Nkwekọrịta a abụghị naanị na-echekwa oghere ala bara uru kamakwa ọ na-eme ka ọ dị mma n’ime ebe ọrụ siri ike. N’ihi ya, ụlọ ọrụ ndị na-arụ ọrụ n’ime oghere nwere ike irite uru site na iji akụrụngwa ha na-arụ ọrụ nke ọma, na-eduga n’ịrụpụta ọrụ nke ọma.

Na mgbakwunye na nhazi ha na-echekwa ohere, LDP electric single beam crane nwere usoro ebuli elu. Crane ndị a na-egosipụtakarị igwe eletriki nke na-enye ike ibuli nke ọma na nke ziri ezi. Emebere igwe eletriki eletrik ka ọ na-arụ ọrụ dị iche iche, na-ahụ na ha nwere ike nabata ihe achọrọ kpọmkwem nke ọrụ ụlọ ọrụ dị iche iche. Ọzọkwa, iji ọkụ eletrik na-eme ka ọrụ dị jụụ ma e jiri ya tụnyere mmanụ dizel ma ọ bụ gas ọzọ, na-eme ka ha dị mma maka gburugburu ebe mbelata mkpọtụ bụ ihe kacha mkpa.

Ejiri cranes ndị a nwere ọtụtụ usoro nchekwa, gụnyere sistemu nchekwa oke ibu yana bọtịnụ nkwụsị ihe mberede. Ihe ndị dị otú ahụ dị mkpa n’igbochi ihe mberede na ịhụ na nchekwa nke ndị ọrụ na ndị ọrụ dị nso. Na mgbakwunye, cranes na-enwekarị njikwa enyi na enyi nke na-enye ndị na-arụ ọrụ aka ijikwa ọrụ ebuli elu na nkenke na mfe. Nke a na-elekwasị anya na nchekwa ọ bụghị nanị na-echebe ndị ọrụ kamakwa na-eme ka arụmọrụ arụmọrụ zuru ezu.

Ọzọkwa, LDP electric single beam cranes bụ maka nrụnye na nhazi dị mfe. Ihe owuwu ha modular na-enye ohere maka mgbakọ kwụ ọtọ, nke nwere ike ibelata oge nhazi nke ọma. Mfe nke nrụnye a bara uru karịsịa maka ụlọ ọrụ na-achọ ntinye ngwa ngwa nke ngwọta ebuli elu. Ọzọkwa, a na-eji cranes eme ihe n’uche, na-eme ka ndị ọrụ na-arụzi ọrụ na-eme nyocha na nrụzi oge na-enweghị nkwụsịtụ. Njirimara a abụghị naanị ịgbatị ogologo ndụ nke akụrụngwa kamakwa ọ na-eme ka ọ nọgide na-arụ ọrụ kacha mma. Enwere ike ịhazi cranes ndị a iji gboo mkpa arụmọrụ, gụnyere ikike ibuli dị iche iche na ogologo ogologo. Ngbanwe a na-eme ka ha dị mma maka ngwa dịgasị iche iche, site na ibuli ígwè ọrụ dị arọ na-ebufe ihe n’ofe ahịrị mmepụta. Ka ụlọ ọrụ na-aga n’ihu na-etolite, ikike ịkpụzi ngwá ọrụ iji gboo mkpa pụrụ iche na-aghọwanye ihe dị mkpa.

N’ikpeazụ, LDP electric single beam cranes na-enye nchikota nke ogologo oge, kọmpat, usoro ebuli elu, njirimara nchekwa, ịdị mfe nke nrụnye, na ntụgharị. . Àgwà ndị a dị mkpa na-eme ka ha bụrụ nhọrọ dị mma maka ngwa mmepụta ihe dị iche iche, na-eme ka mmepụta ihe na-eme ka ọ dịkwuo mma ma na-ahụ maka nchekwa na arụmọrụ. Dị ka ụlọ ọrụ na-achọ ịkwalite ọrụ ha, nnabata nke LDP eletrọnịkị otu beam cranes na-anọchite anya ntinye aka dị mkpa na teknụzụ ebuli elu ọgbara ọhụrụ. Site na ijikọ cranes ndị a n’ime usoro ọrụ ha, ụlọ ọrụ nwere ike nweta nkwalite dị ukwuu na arụmọrụ yana arụmọrụ arụmọrụ.

Key Features of LDP Electric Single Beam Cranes for Industrial Applications

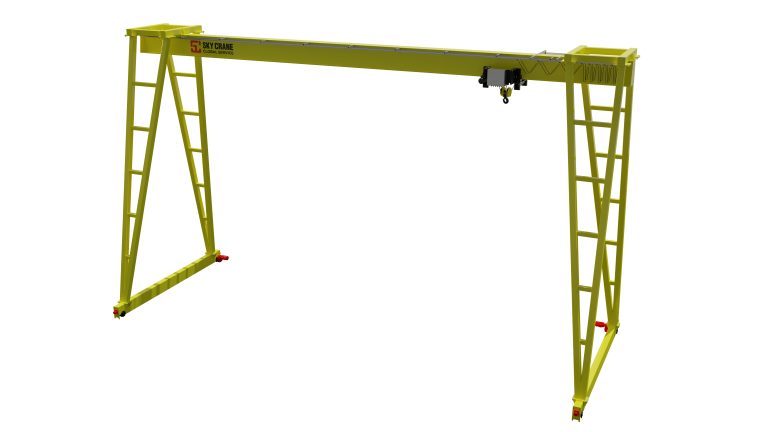

LDP electric single beam cranes are increasingly recognized for their efficiency and versatility in various industrial applications. These cranes are designed to provide reliable lifting solutions, making them indispensable in manufacturing, warehousing, and construction environments. One of the key features of LDP electric single beam cranes is their robust construction, which ensures durability and longevity. Built with high-quality materials, these cranes can withstand the rigors of heavy-duty operations, thereby minimizing maintenance costs and downtime.

Another significant aspect of LDP electric single beam cranes is their compact design. Unlike traditional cranes that require extensive space for operation, the single beam configuration allows for a more streamlined setup. This compactness not only saves valuable floor space but also enhances maneuverability within tight work areas. Consequently, industries that operate in confined spaces can benefit from the efficient use of their facilities, leading to improved productivity.

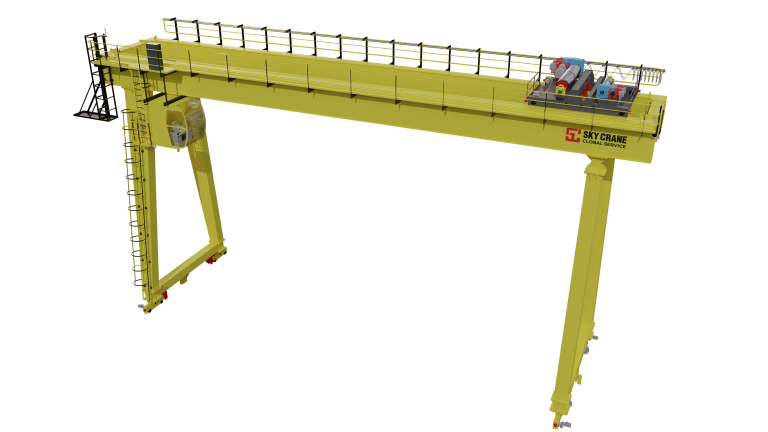

In addition to their space-saving design, LDP electric single beam cranes are equipped with advanced lifting mechanisms. These cranes typically feature electric hoists that provide smooth and precise lifting capabilities. The electric hoists are designed to handle various loads, ensuring that they can accommodate the specific requirements of different industrial tasks. Furthermore, the use of electric power contributes to a quieter operation compared to diesel or gas-powered alternatives, making them suitable for environments where noise reduction is a priority.

Safety is another critical feature of LDP electric single beam cranes. These cranes are equipped with multiple safety mechanisms, including overload protection systems and emergency stop buttons. Such features are essential in preventing accidents and ensuring the safety of operators and nearby personnel. Additionally, the cranes often come with user-friendly controls that allow operators to manage lifting operations with precision and ease. This focus on safety not only protects workers but also enhances overall operational efficiency.

Moreover, LDP electric single beam cranes are designed for easy installation and maintenance. Their modular construction allows for straightforward assembly, which can significantly reduce setup time. This ease of installation is particularly beneficial for businesses that require quick deployment of lifting solutions. Furthermore, the cranes are designed with accessibility in mind, enabling maintenance personnel to perform routine checks and repairs without extensive disassembly. This feature not only prolongs the lifespan of the equipment but also ensures that it remains in optimal working condition.

The versatility of LDP electric single beam cranes is another noteworthy characteristic. These cranes can be customized to meet specific operational needs, including varying lifting capacities and span lengths. This adaptability makes them suitable for a wide range of applications, from lifting heavy machinery to transporting materials across production lines. As industries continue to evolve, the ability to tailor equipment to meet unique demands becomes increasingly important.

In conclusion, LDP electric single beam cranes offer a combination of durability, compactness, advanced lifting mechanisms, safety features, ease of installation, and versatility. These key attributes make them an ideal choice for various industrial applications, enhancing productivity while ensuring safety and efficiency. As businesses seek to optimize their operations, the adoption of LDP electric single beam cranes represents a strategic investment in modern lifting technology. By integrating these cranes into their workflows, industries can achieve significant improvements in both performance and operational effectiveness.