Table of Contents

Uru nke imejuputa ọgụgụ isi Servo Electric Hoists na Factories

Olee otú ndị ọrụ ọkụ eletrik nwere ọgụgụ isi si eme ka arụmọrụ dị mma na arụ ọrụ ụlọ ọrụ

Otu n’ime isi uru nke nwere ọgụgụ isi servo electric hoists bụ ike ha melite arụmọrụ na factory arụmọrụ. Site na iji moto servo na sistemu njikwa dị elu, ndị na-ebuli elu nwere ike ibuli ma bugharịa ibu n’ụzọ ziri ezi na ọsọ ọsọ. Ọ bụghị nanị na nke a na-ebelata oge ọ na-ewe iji rụchaa ọrụ kamakwa ọ na-ebelata ohere nke njehie na ihe mberede, na-eduga na ebe ọrụ dị nchebe maka ndị ọrụ.

Na mgbakwunye na nkenke na ọsọ ha, ndị nwere ọgụgụ isi servo electric hoists na-enwekwa ike ime mgbanwe dị iche iche. ụdị ibu na ọnọdụ ọrụ. Site na ntọala ndị nwere ike ịhazi ya na njiri mara mmemme, enwere ike ịhazi ndị a na-ebuli elu iji gboo mkpa ụlọ ọrụ mmepụta ihe, ma ọ na-ebuli ígwè ọrụ dị arọ ma ọ bụ ihe ndị siri ike. Mgbanwe a na-enye ohere maka mgbanwe dị ukwuu na arụmọrụ ma hụ na a ga-arụcha ọrụ nke ọma na nke ọma.

Ọzọkwa, ndị nwere ọgụgụ isi servo electric hoists nwere ihe mmetụta na sistemụ nlekota nke na-enye data oge na arụmọrụ na ojiji. Enwere ike iji ozi a na-ebuli usoro ọrụ, chọpụta ihe ndị nwere ike ime, yana mee mkpebi ndị a maara nke ọma iji melite arụmọrụ n’ozuzu ya. Site n’inweta data a, ndị na-ahụ maka ụlọ ọrụ nwere ike ịkenye akụrụngwa, nhazi nhazi, na atụmatụ maka mkpa mmepụta n’ọdịnihu.

Uru ọzọ nke nwere ọgụgụ isi servo electric hoists bụ ike arụmọrụ ha. Site n’iji moto servo, ndị a na-ekpu ọkụ na-eri obere ike ma e jiri ya tụnyere igwe ọkụ eletrik ọdịnala, na-ebute ọnụ ahịa ọrụ dị ala yana belata mmetụta gburugburu ebe obibi. Nke a abụghị naanị na-erite uru na ala nke ụlọ ọrụ mmepụta ihe kamakwa ọ dabara na ebumnuche nkwado na ụkpụrụ.

Mba.

Ngwaahịa

| LD eletriki otu beam kreenu | Single – girder Gantry Crane |

| 1 | kreenu ụdị nke Europe |

| 2 | Herbour crane |

| 3 | Nchọpụta ikpe gbasara njikọta nke ọma nke Servo Electric Hoists na ntọala ụlọ ọrụ |

| 4 | Ndị nwere ọgụgụ isi servo electric hoists agbanweela otú ụlọ ọrụ mmepụta ihe si arụ ọrụ, na-enye ụbara arụmọrụ, nchekwa, na nkenke na usoro njikwa ihe. N’isiokwu a, anyị ga-enyocha ụfọdụ ihe ọmụmụ gbasara ijikọ nke ọma nke nwere ọgụgụ isi servo electric hoists na ntọala ụlọ ọrụ, na-egosi uru na mmetụta ha nwere na ọrụ mmepụta ihe. Site n’itinye ndị nwere ọgụgụ isi servo ọkụ eletrik n’ahịrị mgbakọ ha, ụlọ ọrụ ahụ nwere ike ibelata oge na ọrụ achọrọ maka ibuli na ịkwaga akụkụ dị arọ. Ikike njikwa na akpaaka nke hoists nyere ohere ijikọ n’enweghị nkebi na usoro mmepụta dị adị, na-eme ka usoro ọrụ na-aga nke ọma na nke ọma. Ọmụmaatụ ọzọ bụ ụlọ nkwakọba ihe nke na-ejikwa ọnụ ahịa dị elu kwa ụbọchị. Site na iji igwe eletrik servo nwere ọgụgụ isi dochie ndị na-ebu akwụkwọ ntuziaka ọdịnala, ụlọ ọrụ ahụ nwere ike ịbawanye nrụpụta ma belata ihe egwu nke mmerụ ahụ n’ebe ọrụ. Atụmatụ nchekwa dị elu nke ndị na-ebuli elu, dị ka nchebe oke ibu na teknụzụ mgbochi, nyere obi iru ala maka ndị ọrụ na ndị nlekọta, na-ahụ maka ebe ọrụ dị mma. N’ozuzu, nkuchi nke nwere ọgụgụ isi servo electric hoists na ntọala ụlọ ọrụ na-anọchi anya nzọụkwụ dị ịrịba ama iji mee ka ọ dị ọhụrụ na ịkwalite ọrụ mmepụta ihe. Site n’iji ike nke teknụzụ dị elu, ụlọ ọrụ mmepụta ihe nwere ike nweta ọkwa dị elu nke arụmọrụ, nchekwa, na ịdị mma na usoro nhazi ihe ha. N’ikpeazụ, ihe ọmụmụ ndị e gosipụtara n’isiokwu a na-egosi uru a na-ahụ anya na nsonaazụ dị mma nke ijikọ servo eletrik nwere ọgụgụ isi. hoists na ụlọ ọrụ ntọala. Site n’ịkwalite arụpụtaghị ihe na nchekwa ọnụ ahịa gaa na nchekwa nchekwa ebe ọrụ na ịdị mma ngwaahịa, ndị a na-ebuli elu egosila na ha bụ ihe bara uru maka ụlọ nrụpụta ọgbara ọhụrụ. Ka teknụzụ na-aga n’ihu na-aga n’ihu, o doro anya na ndị nwere ọgụgụ isi servo electric hoists ga-arụ ọrụ dị mkpa n’ịkpụzi ọdịnihu nke nrụpụta ụlọ ọrụ na njikwa ihe. |

Moreover, intelligent servo electric hoists are designed to be user-friendly and easy to operate. With intuitive interfaces and remote control capabilities, operators can quickly learn how to use these hoists and perform tasks with minimal training. This reduces the learning curve for new employees and ensures that operations can continue smoothly without interruptions.

Overall, intelligent servo electric hoists play a crucial role in improving efficiency in factory operations. Their precision, adaptability, data monitoring capabilities, energy efficiency, and user-friendly design make them an invaluable asset for modern manufacturing facilities. By investing in these advanced hoists, factories can enhance productivity, reduce costs, and create a safer and more efficient working environment for their employees.

In conclusion, intelligent servo electric hoists are a game-changer for factory operations, offering a wide range of benefits that can significantly improve efficiency and productivity. With their advanced technology and innovative features, these hoists are essential tools for modern manufacturing facilities looking to stay competitive in today’s fast-paced industry.

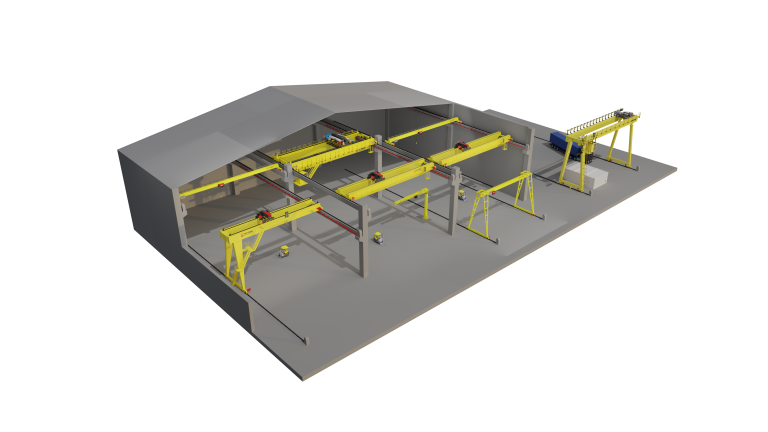

Case Studies of Successful Integration of Intelligent Servo Electric Hoists in Factory Settings

Intelligent servo electric hoists have revolutionized the way factories operate, providing increased efficiency, safety, and precision in material handling processes. In this article, we will explore some case studies of successful integration of intelligent servo electric hoists in factory settings, showcasing the benefits and impact they have had on production operations.

One such case study is a manufacturing plant that specializes in automotive components. By implementing intelligent servo electric hoists in their assembly line, the plant was able to significantly reduce the time and labor required for lifting and moving heavy parts. The hoists’ precise control and automation capabilities allowed for seamless integration with the existing production processes, resulting in a more streamlined and efficient workflow.

Another example is a warehouse facility that handles a high volume of goods on a daily basis. By replacing traditional manual hoists with intelligent servo electric hoists, the facility was able to increase productivity and reduce the risk of workplace injuries. The hoists’ advanced safety features, such as overload protection and anti-sway technology, provided peace of mind for workers and supervisors alike, ensuring a safe working environment.

In a third case study, a metal fabrication plant implemented intelligent servo electric hoists in their material handling operations. The hoists’ ability to precisely position and maneuver heavy metal sheets and components allowed for faster and more accurate production processes. This resulted in a significant reduction in material waste and rework, ultimately leading to cost savings and improved product quality.

The success of these case studies highlights the transformative impact that intelligent servo electric hoists can have on factory settings. By leveraging advanced technology and automation capabilities, factories can optimize their material handling processes, increase productivity, and enhance workplace safety.

Furthermore, the integration of intelligent servo electric hoists in factory settings can also lead to long-term benefits, such as reduced maintenance costs and extended equipment lifespan. The hoists’ smart monitoring and diagnostic features allow for proactive maintenance scheduling, preventing costly breakdowns and downtime.

Overall, the adoption of intelligent servo electric hoists in factory settings represents a significant step towards modernizing and optimizing production operations. By harnessing the power of advanced technology, factories can achieve higher levels of efficiency, safety, and quality in their material handling processes.

In conclusion, the case studies presented in this article demonstrate the tangible benefits and positive outcomes of integrating intelligent servo electric hoists in factory settings. From increased productivity and cost savings to improved workplace safety and product quality, these hoists have proven to be a valuable asset for modern manufacturing facilities. As technology continues to advance, it is clear that intelligent servo electric hoists will play a crucial role in shaping the future of factory automation and material handling.