Table of Contents

Uru nke Iji Bridge Cranes na Factories

Olee otú cranes ogwe aka si eme ka arụmọrụ dị mma na arụ ọrụ ụlọ ọrụ

Ọnụ ọgụgụ

ngwaahịa

| LD eletriki otu beam kreenu | Rubber – Gantry krane ike gwụrụ |

| 1 | kreenu ụdị nke Europe |

| 2 | Herbour crane |

| 3 | Otu n’ime ụzọ cranes ogwe aka na-esi emeziwanye arụmọrụ na arụ ọrụ ụlọ ọrụ bụ site n’ibelata oke ọrụ aka achọrọ iji bugharịa ibu dị arọ. N’oge gara aga, ndị ọrụ ga-eji ígwè ndụdụ ma ọ bụ ngwá ọrụ ndị ọzọ ebuli ma bugharịa ihe ndị dị arọ, nke nwere ike na-ewe oge ma na-achọsi ike. Site na crane ogwe aka, otu onye na-arụ ọrụ nwere ike ibuli ma bugharịa ibu dị arọ site na ịpị bọtịnụ, na-echekwa oge na ibelata ihe ize ndụ nke mmerụ ahụ. si n’otu ebe gaa n’ọzọ. Ogwe aka nwere ike ibuli na ibugharị ibu dị arọ ngwa ngwa na nke ọma, na-ekwe ka ụlọ ọrụ na-eme ka mmepụta ha dịkwuo elu. Nke a nwere ike inyere ụlọ ọrụ aka izute oge njedebe siri ike ma mezuo iwu ndị ahịa n’oge. Enwere ike iji ha ebuli ma bugharịa ihe n’ụzọ kwụ ọtọ, kehoraizin, ma ọ bụ ọbụna n’ịdabere. Mgbanwe a na-eme ka cranes ogwe aka bụrụ ngwá ọrụ dị mkpa maka ụlọ ọrụ ndị chọrọ ịkwaga ihe n’akụkụ dị iche iche. Na mgbakwunye na imeziwanye arụmọrụ, ogwe aka nwekwara ike inyere ụlọ ọrụ aka ịchekwa ohere. N’ihi na a na-agbanye kreenụ ogwe aka n’elu, ha anaghị eburu oghere ala bara uru dị ka ụdị ngwá ọrụ ndị ọzọ na-ebuli elu. Nke a na-enye ohere ka ụlọ ọrụ na-ebuli ohere ha nwere ike iji rụọ ọrụ ma hazie ihe ha nke ọma. |

| 4 | N’ozuzu, ogwe aka cranes bụ ngwá ọrụ dị mkpa maka imeziwanye arụmọrụ na arụmọrụ ụlọ ọrụ. Site n’ibelata ọnụ ọgụgụ ọrụ aka achọrọ, ịbawanye ọsọ nke ihe nwere ike ịkwaga, na ịchekwa ohere, cranes ogwe aka nwere ike inyere ụlọ ọrụ aka ịbawanye mmepụta ha ma nọgide na-asọmpi na gburugburu ebe nrụpụta ngwa ngwa taa. Ma ejiri ya maka ibuli ibu dị arọ, ibu ihe, ma ọ bụ ịhazi ngwa ahịa, cranes ogwe aka bụ ihe bara uru maka ụlọ ọrụ mmepụta ihe ọ bụla na-achọ imeziwanye arụmọrụ na ịhazi ọrụ ha. |

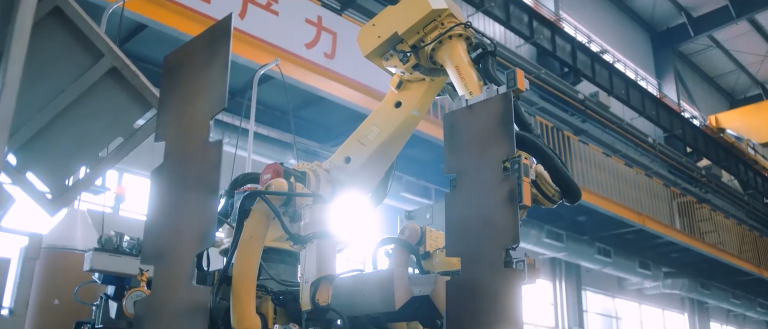

One of the main ways that arm cranes improve efficiency in factory operations is by reducing the amount of manual labor required to move heavy loads. In the past, workers would have to use forklifts or other equipment to lift and move heavy items, which could be time-consuming and physically demanding. With an arm crane, a single operator can easily lift and move heavy loads with the push of a button, saving time and reducing the risk of injury.

Another way that arm cranes improve efficiency is by increasing the speed at which materials can be moved from one location to another. Arm cranes are capable of lifting and moving heavy loads quickly and efficiently, allowing factories to increase their production output. This can help factories meet tight deadlines and fulfill customer orders in a timely manner.

Arm cranes are also highly versatile, allowing them to be used in a wide range of applications within a factory setting. They can be used to lift and move materials vertically, horizontally, or even on an incline. This flexibility makes arm cranes an essential tool for factories that need to move materials in various directions.

In addition to improving efficiency, arm cranes can also help factories save space. Because arm cranes are mounted overhead, they do not take up valuable floor space like other types of lifting equipment. This allows factories to maximize their usable space and organize their materials more efficiently.

Overall, arm cranes are an essential tool for improving efficiency in factory operations. By reducing the amount of manual labor required, increasing the speed at which materials can be moved, and saving space, arm cranes can help factories increase their productivity and stay competitive in today’s fast-paced manufacturing environment. Whether used for lifting heavy loads, transporting materials, or organizing inventory, arm cranes are a valuable asset for any factory looking to improve efficiency and streamline their operations.