Table of Contents

Pomaikai o ka hoohana ana i na Hoist Servo Uila ma na Hale Hana

Ke hoʻololi nei nā hoists uila servo akamai i ke ʻano o ka hana ʻana o nā hale hana, e hāʻawi ana i kahi ākea o nā pōmaikaʻi e hiki ke hoʻomaikaʻi nui i ka pono, ka huahana, a me ka palekana ma kahi hana. Hoʻolako ʻia kēia mau hoists holomua me ka ʻenehana ʻokiʻoki e hiki ai ke kaohi pololei a me ka automation o nā hana hāpai ʻana, e hoʻolilo iā lākou i mea hana pono no nā hale hana hou. hoʻonui i ka huahana. Hoʻolālā ʻia kēia mau hoists e hana i nā hana me ka wikiwiki a me ka pololei, e hōʻemi ana i ka manawa e hoʻopau ai i nā hana hāpai. Me kā lākou mau ʻōnaehana hoʻokele holomua, hiki i nā mea hana ke hoʻoponopono maʻalahi i ka wikiwiki a me ke kūlana o ka hoist, e ʻae i ka neʻe wikiwiki a me ka maikaʻi o nā mea a me nā huahana ma ka papahele o ka hale hana. Hiki i kēia hoʻonui huahana ke alakaʻi i nā pae kiʻekiʻe a me ka hoʻomaikaʻi ʻana i ka pono holoʻokoʻa i ke kaʻina hana.

Ma waho aʻe o ka hoʻonui ʻana i ka huahana, hoʻomaikaʻi pū nā hoists uila servo akamai i ka palekana ma kahi hana. Hoʻolako ʻia kēia mau hoists me nā hiʻohiʻona palekana holomua e like me ka pale ʻana i ka overload, ʻenehana anti-sway, a me nā hana hoʻomaha pilikia, e kōkua i ka pale ʻana i nā pōʻino a me nā ʻeha i ka wā o ka hāpai ʻana. Ma ka automate ana i kekahi mau hana a me ka hoemi ana i ka pono no ka hana lima, hiki i keia mau hoists ke hoemi i ka pilikia o ka hewa kanaka a me ka hooiaio ana i ka maluhia o ka hana no na limahana. hoʻonohonoho pono a me ka neʻe ʻana o nā mea. He mea koʻikoʻi kēia kikoʻī i nā ʻoihana kahi koʻikoʻi o ka hoʻokomo pono ʻana i nā ukana kaumaha, e like me nā ʻāpana kaʻa a i ʻole aerospace. Me kā lākou mau ʻōnaehana hoʻokele holomua, hiki i kēia mau hoists ke hana i nā hana hoʻokiʻekiʻe paʻakikī me ka maʻalahi, e hōʻoia i ka mālama ʻia ʻana o nā huahana me ka mālama a me ka pololei i ke kaʻina hana. Hiki ke hoʻohui maʻalahi kēia mau hoists i nā laina hana e kū nei a hoʻonohonoho pono ʻia e hoʻokō i nā koi kikoʻī, e hoʻolilo iā lākou i mea maʻalahi a hiki ke hoʻololi ʻia no ka nui o nā noi. ʻO ka hāpai ʻana i nā mīkini koʻikoʻi, ka lawe ʻana i nā mea ma waena o nā hale hana, a i ʻole ka hui ʻana i nā huahana ma ka laina hui, hiki i nā hoists uila servo akamai ke hoʻololi i nā hana a me ka hoʻomaikaʻi ʻana i ka hana holoʻokoʻa i kēlā me kēia hana hana. mālama koʻikoʻi nui a me ka hoʻomaikaʻi ʻana i ka hana. Ma ka hoʻonui ʻana i ka huahana, hoʻonui i ka palekana, a me ka hāʻawi ʻana i ka mana pololei ma luna o nā hana hāpai, hiki i kēia mau hoists ke kōkua i nā mea hana e hoʻokō i kā lākou mau kaʻina hana a loaʻa i nā pae kiʻekiʻe o ka pono a me ka loaʻa kālā. Me kā lākou ʻenehana kiʻekiʻe a me nā hiʻohiʻona hou, ke hoʻolālā nei nā servo electric hoists i ka wā e hiki mai ana o ka hana ʻana a me ka hoʻololi ʻana i ke ʻano o ka hana ʻana o nā hale hana i ke kenekulia 21.

Pehea e hoʻomaikaʻi ai ka naʻauao Servo Electric Hoists i ka pono ma nā hana hale hana

Ua hoʻololi hou nā hoists uila servo akamai i ke ʻano o ka hana ʻana o nā hale hana, e hāʻawi ana i kahi ala ʻoi aku ka maikaʻi a maʻalahi i ka hāpai ʻana a me ka hoʻoneʻe ʻana i nā ukana kaumaha. Hoʻolako ʻia kēia mau hoists me ka ʻenehana holomua e hiki ai ke kāohi pololei a me ka automation, e hana ana iā lākou i mea pono no nā hale hana hou.

ʻAʻole.

| Huahana | LD uila hoʻokahi kuʻo crane |

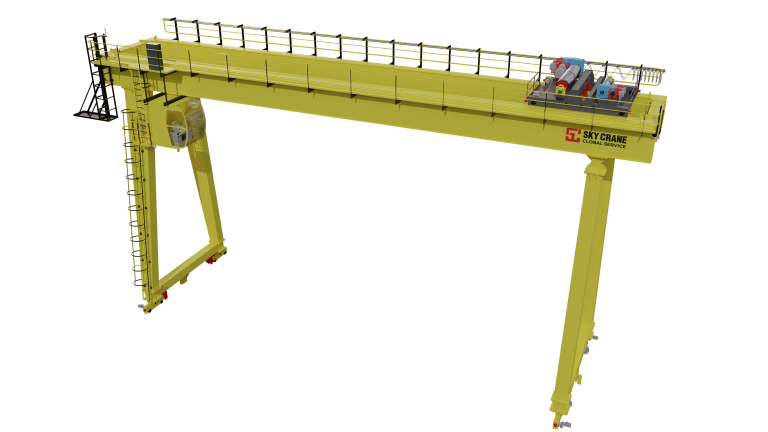

| 1 | Single – girder Gantry Crane |

| 2 | ʻano crane ʻEulopa |

| 3 | Eia kekahi, ua hoʻolālā ʻia nā hoists uila servo akamai i mea hoʻohana a maʻalahi hoʻi e hana. Me nā intuitive interfaces a me ka mana mamao, hiki i nā mea hana ke aʻo koke i ka hoʻohana ʻana i kēia mau hoists a hana i nā hana me ka liʻiliʻi o ka hoʻomaʻamaʻa. Hoʻemi kēia i ke aʻo ʻana no nā limahana hou a hōʻoia i ka hiki ke hoʻomau pono nā hana me ka ʻole o ke keakea. ʻO kā lākou pololei, hiki ke hoʻololi, hiki ke nānā i ka ʻikepili, ka ikaika o ka ikehu, a me ka hoʻolālā ʻoluʻolu e hoʻohana iā lākou i waiwai waiwai no nā hale hana hou. Ma ka hoʻokomo kālā ʻana i kēia mau hoists holomua, hiki i nā hale hana ke hoʻonui i ka huahana, hoʻemi i nā kumukūʻai, a hana i kahi ʻoihana palekana a ʻoi aku ka maikaʻi no kā lākou poʻe limahana. nā pono e hiki ke hoʻomaikaʻi nui i ka pono a me ka huahana. Me kā lākou ʻenehana kiʻekiʻe a me nā hiʻohiʻona hou, ʻo kēia mau hoists he mau mea pono pono no nā hale hana hou e nānā nei e noho hoʻokūkū i ka ʻoihana wikiwiki o kēia mau lā. |

| 4 | Nā Haʻawina no ka hoʻohui kūleʻa ʻana o nā hoist Servo Electric ma nā ʻōnaehana hale hana |

Ua hoʻololi hou nā hoists uila servo akamai i ke ʻano o ka hana ʻana o nā hale hana, me ka hoʻonui ʻana i ka pono, palekana, a me ka pololei i nā kaʻina hana hoʻokele waiwai. Ma kēia ‘atikala, e ‘imi ana mākou i kekahi mau hihia no ka ho’ohui ‘ana i nā hoists uila servo akamai i loko o nā hale hana, e hō’ike ana i nā pono a me ka hopena i loa’a iā lākou ma nā hana hana.

O kekahi o ia hihia he hale hana hana kūikawā i nā mea ka’a. Ma ka hoʻokō ʻana i nā hoists uila servo akamai i kā lākou laina hui, ua hiki i ka mea kanu ke hōʻemi nui i ka manawa a me ka hana e pono ai no ka hāpai ʻana a me ka neʻe ʻana i nā ʻāpana kaumaha. ʻAe ʻia ka mana pololei a me ka mana automation o ka hoists no ka hoʻohui pono ʻana me nā kaʻina hana e kū nei, e hopena i kahi kaʻina hana maʻalahi a maikaʻi. Ma ka hoʻololi ʻana i nā hoists manual kuʻuna me nā hoists uila servo akamai, ua hiki i ka hale ke hoʻonui i ka huahana a hōʻemi i ka hopena o nā ʻeha ma kahi hana. ʻO nā hiʻohiʻona palekana kiʻekiʻe o ka hoists, e like me ka pale ʻana i ka ukana a me ka ʻenehana anti-sway, hāʻawi i ka maluhia o ka noʻonoʻo no nā limahana a me nā luna hoʻokele like, e hōʻoia ana i kahi wahi hana palekana. i kā lākou hana hoʻoponopono waiwai. Hiki i ka poʻe hoists ke hoʻonohonoho pololei a hoʻololi i nā ʻāpana metala kaumaha a me nā ʻāpana i ʻae ʻia no nā kaʻina hana wikiwiki a pololei. ʻO kēia ka hopena i ka hoʻemi nui ʻana o ka ʻōpala waiwai a me ka hana hou ʻana, i ka hopena i ka mālama ʻana i ke kumukūʻai a me ka hoʻomaikaʻi ʻana i ka maikaʻi o ka huahana.

Ma ka hoʻohana ʻana i ka ʻenehana kiʻekiʻe a me nā mana automation, hiki i nā hale hana ke hoʻonui i kā lākou mau kaʻina hana, hoʻonui i ka huahana, a hoʻonui i ka palekana o ka wahi hana. nā koina mālama a me ka lōʻihi o ke ola o nā mea hana. ʻO nā hiʻohiʻona mākaʻikaʻi akamai a me nā hiʻohiʻona diagnostic e ʻae ai i ka hoʻonohonoho ʻana i ka mālama ʻana, ka pale ʻana i nā haʻihaʻi kumu kūʻai a me ka manawa haʻahaʻa. Ma ka hoʻohana ʻana i ka mana o ka ʻenehana kiʻekiʻe, hiki i nā hale hana ke hoʻokō i nā kiʻekiʻe kiʻekiʻe o ka pono, palekana, a me ka maikaʻi i kā lākou kaʻina hana hoʻokele waiwai.

I ka hopena, hōʻike nā hihia i hōʻike ʻia ma kēia ʻatikala i nā pōmaikaʻi maoli a me nā hopena maikaʻi o ka hoʻohui ʻana i ka uila servo akamai. hoists i loko o ka hale hana. Mai ka hoʻonui ʻana i ka huahana a me ka mālama ʻana i ke kumukūʻai i ka hoʻomaikaʻi ʻana i ka palekana o ka wahi hana a me ka maikaʻi o ka huahana, ua hōʻike ʻia kēia mau hoists he waiwai waiwai no nā hale hana hou. Ke hoʻomau nei ka ʻenehana i ka holomua, ʻike maopopo ʻia ka hana koʻikoʻi o ka servo electric hoists i ka hoʻolālā ʻana i ka wā e hiki mai ana o ka automation ʻoihana a me ka hoʻokele waiwai.

Case Studies of Successful Integration of Intelligent Servo Electric Hoists in Factory Settings

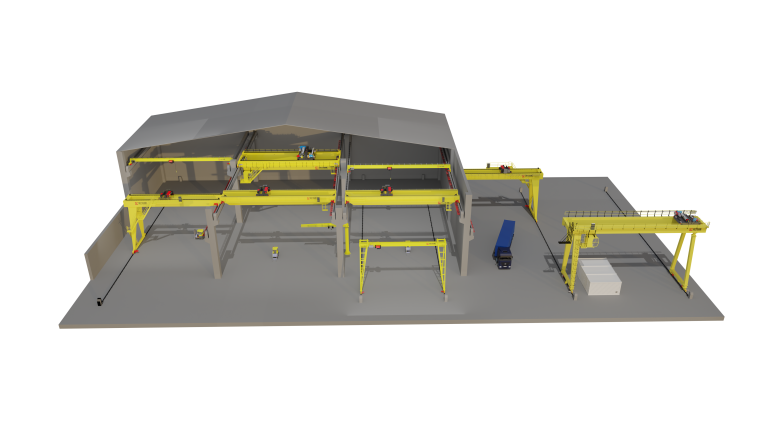

Intelligent servo electric hoists have revolutionized the way factories operate, providing increased efficiency, safety, and precision in material handling processes. In this article, we will explore some case studies of successful integration of intelligent servo electric hoists in factory settings, showcasing the benefits and impact they have had on production operations.

One such case study is a manufacturing plant that specializes in automotive components. By implementing intelligent servo electric hoists in their assembly line, the plant was able to significantly reduce the time and labor required for lifting and moving heavy parts. The hoists’ precise control and automation capabilities allowed for seamless integration with the existing production processes, resulting in a more streamlined and efficient workflow.

Another example is a warehouse facility that handles a high volume of goods on a daily basis. By replacing traditional manual hoists with intelligent servo electric hoists, the facility was able to increase productivity and reduce the risk of workplace injuries. The hoists’ advanced safety features, such as overload protection and anti-sway technology, provided peace of mind for workers and supervisors alike, ensuring a safe working environment.

In a third case study, a metal fabrication plant implemented intelligent servo electric hoists in their material handling operations. The hoists’ ability to precisely position and maneuver heavy metal sheets and components allowed for faster and more accurate production processes. This resulted in a significant reduction in material waste and rework, ultimately leading to cost savings and improved product quality.

The success of these case studies highlights the transformative impact that intelligent servo electric hoists can have on factory settings. By leveraging advanced technology and automation capabilities, factories can optimize their material handling processes, increase productivity, and enhance workplace safety.

Furthermore, the integration of intelligent servo electric hoists in factory settings can also lead to long-term benefits, such as reduced maintenance costs and extended equipment lifespan. The hoists’ smart monitoring and diagnostic features allow for proactive maintenance scheduling, preventing costly breakdowns and downtime.

Overall, the adoption of intelligent servo electric hoists in factory settings represents a significant step towards modernizing and optimizing production operations. By harnessing the power of advanced technology, factories can achieve higher levels of efficiency, safety, and quality in their material handling processes.

In conclusion, the case studies presented in this article demonstrate the tangible benefits and positive outcomes of integrating intelligent servo electric hoists in factory settings. From increased productivity and cost savings to improved workplace safety and product quality, these hoists have proven to be a valuable asset for modern manufacturing facilities. As technology continues to advance, it is clear that intelligent servo electric hoists will play a crucial role in shaping the future of factory automation and material handling.