Table of Contents

Amfanin Amfani da Cranes Gada a Masana’antu

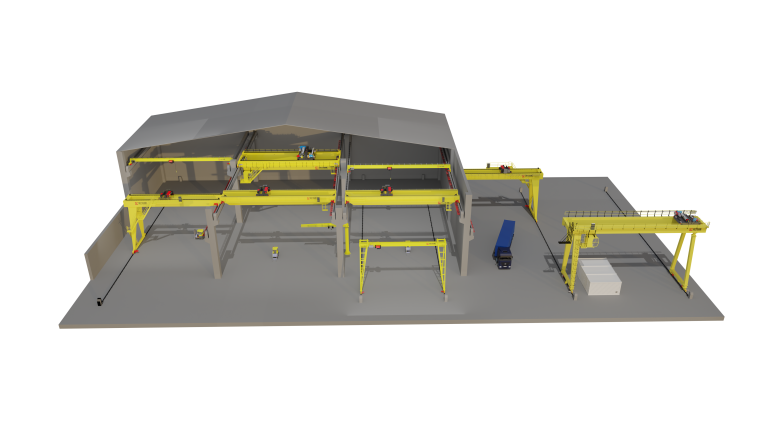

Yadda Hannun Hannu ke inganta Ingantacciyar Aiki a Ma’aikata

Lambar

samfur

| LD lantarki guda katako crane | Rubber – gaji Gantry Crane |

| 1 | Krane irin na Turai |

| 2 | Harbour crane |

| 3 | Daya daga cikin manyan hanyoyin da kekunan hannu ke inganta aiki a cikin ayyukan masana’anta shine ta hanyar rage yawan aikin hannu da ake buƙata don ɗaukar kaya masu nauyi. A da, ma’aikata za su yi amfani da kayan aiki na forklift ko wasu kayan aiki don ɗagawa da motsa abubuwa masu nauyi, waɗanda za su iya ɗaukar lokaci kuma suna buƙatar jiki. Tare da crane na hannu, ma’aikaci guda ɗaya zai iya ɗauka cikin sauƙi da motsa kaya masu nauyi tare da danna maɓallin, yana adana lokaci da rage haɗarin rauni. ya koma wani wuri. Crane na hannu suna iya ɗagawa da motsa kaya masu nauyi cikin sauri da inganci, wanda ke ba da damar masana’antu su ƙara yawan abubuwan da suke samarwa. Wannan na iya taimaka wa masana’antu su cika ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun bayanai da kuma cika umarni na abokan ciniki a cikin lokaci. Ana iya amfani da su don ɗagawa da motsa kayan a tsaye, a kwance, ko ma a kan karkata. Wannan sassauƙan ya sa cranes ɗin hannu ya zama kayan aiki mai mahimmanci ga masana’antu waɗanda ke buƙatar motsa kayan a wurare daban-daban. Domin ana hawa cranes na hannu sama, ba sa ɗaukar sararin bene mai mahimmanci kamar sauran nau’ikan kayan ɗagawa. Wannan yana ba wa masana’antu damar haɓaka sararin da ake amfani da su da kuma tsara kayan aikin su yadda ya kamata. |

| 4 | Gaba ɗaya, cranes hannu sune kayan aiki mai mahimmanci don haɓaka haɓaka aiki a cikin ayyukan masana’anta. Ta hanyar rage yawan aikin hannu da ake buƙata, haɓaka saurin da za a iya motsa kayan, da adana sararin samaniya, cranes na hannu na iya taimakawa masana’antu haɓaka haɓakar su kuma su kasance masu fa’ida a cikin yanayin masana’anta na yau da kullun. Ko ana amfani da su don ɗaukar kaya masu nauyi, kayan jigilar kayayyaki, ko tsara kaya, cranes na hannu suna da mahimmanci ga kowace masana’anta da ke neman haɓaka haɓaka aiki da daidaita ayyukansu. |

One of the main ways that arm cranes improve efficiency in factory operations is by reducing the amount of manual labor required to move heavy loads. In the past, workers would have to use forklifts or other equipment to lift and move heavy items, which could be time-consuming and physically demanding. With an arm crane, a single operator can easily lift and move heavy loads with the push of a button, saving time and reducing the risk of injury.

Another way that arm cranes improve efficiency is by increasing the speed at which materials can be moved from one location to another. Arm cranes are capable of lifting and moving heavy loads quickly and efficiently, allowing factories to increase their production output. This can help factories meet tight deadlines and fulfill customer orders in a timely manner.

Arm cranes are also highly versatile, allowing them to be used in a wide range of applications within a factory setting. They can be used to lift and move materials vertically, horizontally, or even on an incline. This flexibility makes arm cranes an essential tool for factories that need to move materials in various directions.

In addition to improving efficiency, arm cranes can also help factories save space. Because arm cranes are mounted overhead, they do not take up valuable floor space like other types of lifting equipment. This allows factories to maximize their usable space and organize their materials more efficiently.

Overall, arm cranes are an essential tool for improving efficiency in factory operations. By reducing the amount of manual labor required, increasing the speed at which materials can be moved, and saving space, arm cranes can help factories increase their productivity and stay competitive in today’s fast-paced manufacturing environment. Whether used for lifting heavy loads, transporting materials, or organizing inventory, arm cranes are a valuable asset for any factory looking to improve efficiency and streamline their operations.