New Chinese BNRT crab model explosion-proof electric hoist

新中式防爆电动葫芦是我公司在新型中国电动葫芦的基础上开发的一系列防爆电动葫芦之一,具有结构紧凑、性能优良、安全可靠、性能优良等特点。

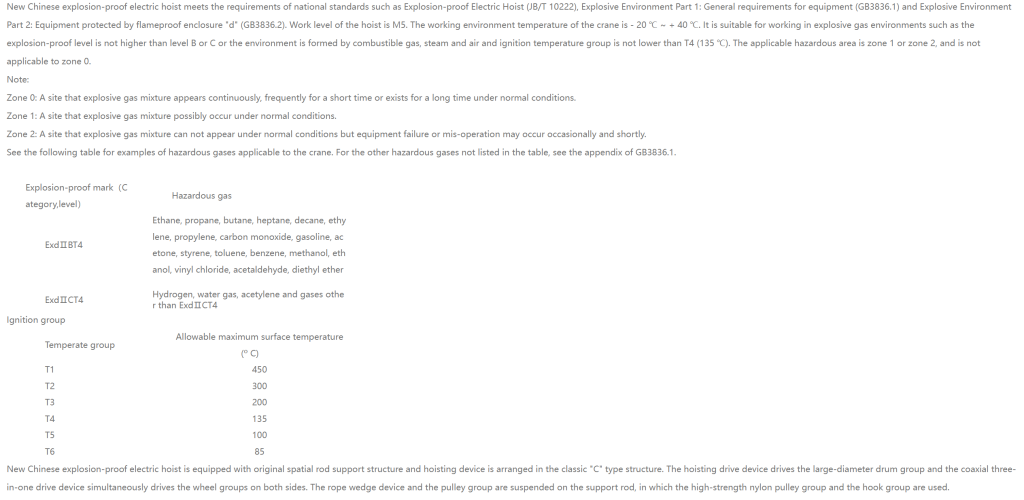

——————————————————Product Advantages:

(1)Independent and controllable core technology

Cooperate with key universities and research institutions to develop core parts and components, and manufacture completely independently to achieve controllable product quality and delivery time.

The motor is an explosion-proof three-phase induction motor with variable frequency

electromagnetic braking. The speed of the motor is stable, with large overload capacity and high mechanical strength, which is especially suitable for equipment with short-time or intermittent operation and frequent hoisting and braking. The standard insulation grade of the motor is F and the protection grade is IP65.

Reducer adopts a fully enclosed hardened face gear. After carburizing and quenching, the gear face hardness can reach 58-62HRC, with high bearing capacity and low working noise. The reducer case cover has high strength and good performance. The reducer has a second brake interface, which can greatly meet the user’s requirements.

(2)Modular design

Four hoisting drives and two running drives can match with full series 1-20t new Chinese electric hoist; The same hoisting devices can be used in four structures: standard headroom mode, low headroom mode, crab running type mode and fixed type mode.

(3)Compact structure and small limit of size

All series adopt large-diameter drums, which can effectively increase the hoisting height and reduce the left and right limits. Smaller working blind area of the crane can provide users with greater use space.

(4)Maintenance free, energy saving and environmental protection design concept

a.Reducer with high-precision hardened face gear has been filled with world famous brand lubricating oil before delivery, and it does not need to be replaced within the product life cycle.

b.Adopt world famous brand and maintenance free steel rope.

c.High-strength nylon fairlead, upgrading from vulnerable parts to durable goods.

d.The electromagnetic disc brake has the functions of automatic brake clearance compensation and maintenance free.

e.The motor power is reduced by 30% compared with the traditional electric hoist.

Work efficiency is increased by more than 20%

f.through the application of frequency conversion positioning technology.

g.The noise of the whole machine is below 70 dB.

h.Brake pads of the brake is designed without asbestos.

i.The sliding friction among the nylon fairlead, steel rope and the drum will not produce metal dust, providing high clean operation space for workers.

(5)Intelligent, remote maintenance design concept

a.Security monitor

b.Big data management, cloud platform connection

c.Real-time monitoring by mobile APP

——————————————————Performance Parameters:

Lifting capacity: 3t~30t

Lifting height: 6m~30m

Work level: M3~M5