Table of Contents

Top Lifting Equipment Manufacturers in China

China has established itself as a global leader in manufacturing, particularly in the realm of lifting equipment. This sector is crucial for various industries, including construction, logistics, and manufacturing, where the safe and efficient movement of heavy materials is paramount. As a result, numerous manufacturers have emerged, each vying for a share of the international market. Among these, several companies stand out due to their commitment to quality, innovation, and customer service.

One of the most prominent names in the lifting equipment industry is Zhejiang Heli Co., Ltd. Founded in 1958, Heli has grown to become one of the largest forklift manufacturers in China. The company specializes in a wide range of lifting equipment, including electric and internal combustion forklifts, as well as warehouse equipment. Heli’s commitment to research and development has led to the creation of advanced technologies that enhance the efficiency and safety of their products. Furthermore, their extensive distribution network ensures that customers worldwide can access their high-quality equipment.

Another key player in the Chinese lifting equipment market is Anhui Heli Industrial Vehicle Co., Ltd. This company has made significant strides in the production of electric forklifts and other material handling equipment. Anhui Heli is known for its focus on sustainability, as it actively develops eco-friendly lifting solutions that reduce energy consumption and emissions. Their innovative approach not only meets the demands of modern industries but also aligns with global efforts to promote environmental responsibility.

In addition to these established manufacturers, newer companies like XCMG Group have also made a significant impact on the lifting equipment landscape. Founded in 1989, XCMG has rapidly expanded its product offerings to include a wide range of construction machinery, including cranes and aerial work platforms. The company is recognized for its commitment to quality and has received numerous certifications that attest to the reliability of its products. XCMG’s focus on international expansion has allowed it to establish a strong presence in markets across Asia, Europe, and North America.

Moreover, SANY Group is another noteworthy manufacturer that has gained recognition for its innovative lifting equipment. Established in 1989, SANY has become one of the largest construction machinery manufacturers in the world. The company produces a diverse range of lifting equipment, including tower cranes and truck-mounted cranes, which are widely used in large-scale construction projects. SANY’s emphasis on technological advancement and quality control has positioned it as a trusted brand among global customers.

As the demand for lifting equipment continues to grow, Chinese manufacturers are increasingly focusing on enhancing their production capabilities and expanding their product lines. This trend is evident in companies like JLG Industries, which, although originally an American company, has established manufacturing facilities in China to leverage the country’s cost advantages while maintaining high standards of quality. This strategic move allows JLG to offer competitive pricing while ensuring that their products meet the rigorous safety and performance standards expected by customers worldwide.

In conclusion, the lifting equipment manufacturing sector in China is characterized by a diverse array of companies that excel in quality, innovation, and customer service. From established giants like Zhejiang Heli and Anhui Heli to emerging players like XCMG and SANY, these manufacturers are well-equipped to meet the growing demands of industries around the globe. As they continue to innovate and expand their reach, it is clear that China will remain a pivotal player in the global lifting equipment market for years to come.

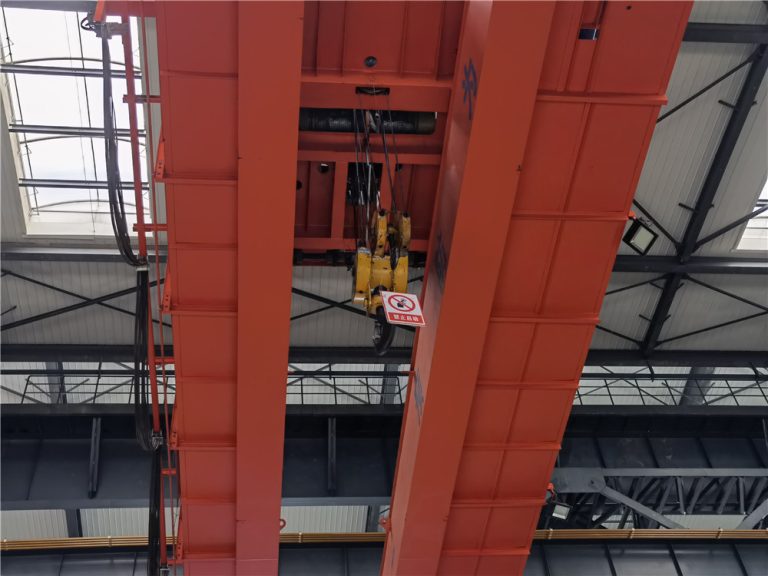

Key Features of High-Quality Lifting Equipment for Factories

When it comes to the efficiency and safety of operations in factories, the quality of lifting equipment plays a pivotal role. High-quality lifting equipment is essential for ensuring that heavy loads are moved safely and effectively, thereby minimizing the risk of accidents and enhancing productivity. One of the key features of such equipment is its robust construction. High-quality lifting devices are typically made from durable materials that can withstand the rigors of daily use in demanding environments. This durability not only extends the lifespan of the equipment but also reduces the frequency of maintenance and replacement, which can be costly for factories.

| Serial Number | Products |

| 1 | LX electric suspension crane |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another important feature is the load capacity of the lifting equipment. High-quality devices are designed to handle specific weight limits, and it is crucial for factories to select equipment that meets their operational needs. This ensures that the equipment can safely lift and transport heavy materials without the risk of failure. Furthermore, reputable manufacturers often provide detailed specifications regarding load capacities, which helps factory managers make informed decisions when selecting lifting equipment.

In addition to load capacity, the versatility of lifting equipment is a significant consideration. High-quality lifting devices often come with various attachments and accessories that allow them to perform multiple functions. For instance, cranes, hoists, and forklifts can be equipped with different types of hooks, slings, or forks, enabling them to handle a wide range of materials and loads. This versatility not only enhances operational efficiency but also allows factories to adapt to changing production requirements without the need for extensive investment in new equipment.

Safety features are another hallmark of high-quality lifting equipment. Leading manufacturers prioritize the incorporation of advanced safety mechanisms, such as overload protection systems, emergency stop buttons, and automatic braking systems. These features are designed to prevent accidents and ensure that operators can work confidently, knowing that the equipment is equipped to handle unexpected situations. Additionally, many high-quality lifting devices are designed with ergonomic considerations in mind, reducing the physical strain on operators and promoting a safer working environment.

Moreover, ease of use is a critical aspect of high-quality lifting equipment. User-friendly controls and intuitive designs facilitate smooth operation, allowing workers to quickly become proficient in using the equipment. This not only enhances productivity but also reduces the likelihood of operator error, which can lead to accidents or damage to materials. Training programs provided by manufacturers can further enhance the effectiveness of lifting equipment by ensuring that operators are well-versed in its proper use and maintenance.

Lastly, the availability of after-sales support and service is a vital feature that distinguishes high-quality lifting equipment. Reputable manufacturers often offer comprehensive warranties and readily accessible customer service, ensuring that any issues can be promptly addressed. This support is crucial for maintaining the equipment’s performance and longevity, as well as for minimizing downtime in factory operations.

In conclusion, the key features of high-quality lifting equipment for factories encompass robust construction, appropriate load capacity, versatility, advanced safety mechanisms, ease of use, and reliable after-sales support. By prioritizing these features, factory managers can ensure that they invest in lifting equipment that not only meets their operational needs but also enhances safety and productivity in the workplace. As factories continue to evolve and adapt to new challenges, the importance of selecting high-quality lifting equipment cannot be overstated.